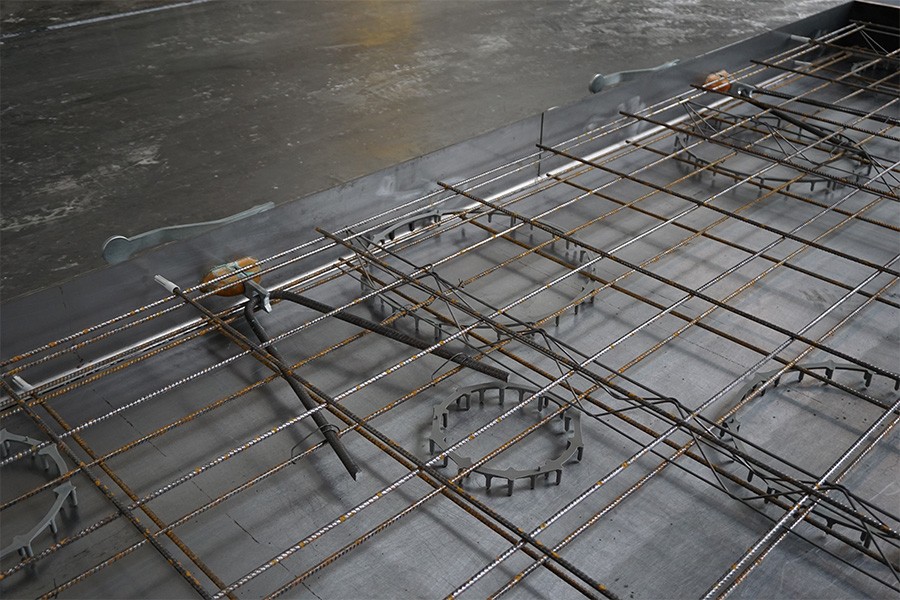

UniForm® formwork system in use at the Dutch company Bisoton

Bisoton B.V., based in Ede, the Netherlands, has chosen the UniForm® formwork system for the expansion of its production. The formwork system is particularly convincing due to the usable flexibility and speed in the production process.

UniForm® is a permanently usable steel formwork facing with a screw connection mechanism on the back. The advantage of the system is the quick change on the BT MultiForm carrier. The formwork beam system can be positioned precisely with the MagFly®AP magnet and fixed to the formwork table.

The BT formwork system was planned and delivered by BT innovation’s Dutch partner Hakron-Terwa as part of the equipment for four tilt tables á 25 x 5 m. The quick assembly of the formwork, the rapid setting and activation of the MagFly®AP magnets, provide measurable time savings. The chamfers convince with a high quality on the precast element and, last but not least, the consumption of formwork timber could be reduced enormously. At the same time, this is associated with a noticeable reduction in disposal costs and thus more environmentally friendly production.

Learn more about this project here.