Manhole sealing with BT innovation

Manhole structures are essential parts of the sewer networks through which the supply and disposal of buildings, factories and communities with media such as gas, water, sewage, ventilation, electricity and telecommunications but sometimes also only basic drainage takes place. Ultimately, many pipes together almost always lead to manholes and sewers at some point. In addition, there are numerous access and maintenance manholes at underground facilities or to sewer systems that are used for inspection, cleaning or rehabilitation. Even the aeration aspect of the wastewater on its way to the treatment plant is important.

BT sealing products are excellent for this purpose:

- Repair structural defects and leaks in sewers and manholes

- Reliable sealing for retrofitting as well as for new manholes

Thus, manhole sealing can be realized quickly and easily with products from B.T. innovation.

BT solutions for reliable manhole sealing

In order to be able to seal the manhole systems safely against groundwater or leaking wastewater right at the beginning of the construction process, the planning should be carried out with care. Subsequent improvements to problem areas are possible. For new construction and repair, B.T. innovation provides various products that will simplify sealing.

Causes of leaks

Many manholes and channels made of precast concrete or reinforced concrete consist of frame culverts. Smaller manholes usually contain a manhole base, manhole rings and an upper cover component. Channels and manholes are subject to movement in the subsoil, subsidence, frost, road traffic, root damage or chemical attack by sewage.

Over time, it is precisely the daily loads such as traffic loads and aggressive wastewater that cause manholes to become damaged or leak. This can cause damage to concrete and sealing such as surface damage, corrosion, cracking or leaking joints. For this reason, these structures must be regularly inspected, maintained and rehabilitated.

RubberElast® – joint tape for sealing in new sewers and manholes

The sealing of new channels and manholes can already be carried out during the installation of the frame culverts and concrete elements with RubberElast® and the B.T. Turnbuckle®. Concrete rings can be sealed with RubberElast® alone during installation, while all these civil engineering structures can be subsequently sealed or refurbished with InnoElast® Type 2.

The RubberElast® tape is easy and quick to process without any additional aids. For manhole rings, the self-adhesive tape is placed on the clean contact surface. Then the next manhole ring is put on dry – done. The weight of the upper ring compresses the RubberElast® and permanently seals the joint. Assembly, sealing and filling are thus possible in one day.

Advantages of RubberElast®:

- Simplest processing

- Immediately after mounting waterproof

- Processing even at low temperatures from -10°C

- Tested pressure waterproof up to 5 m water column

- Waste water, acid, alkali, salt resistant

Application:

RubberElast® can be processed quickly and without further aids. It is self-adhesive and is glued to one side of a component surface. The precast parts are then assembled and the RubberElast® is compressed in the component joint so that the component joint is filled. The joint is immediately watertight after grouting. The material remains permanently elastic and thus seals the joints permanently. Installation should be carried out in the temperature range from -10 °C to +40 °C. RubberElast® retains its elasticity even at low temperatures.

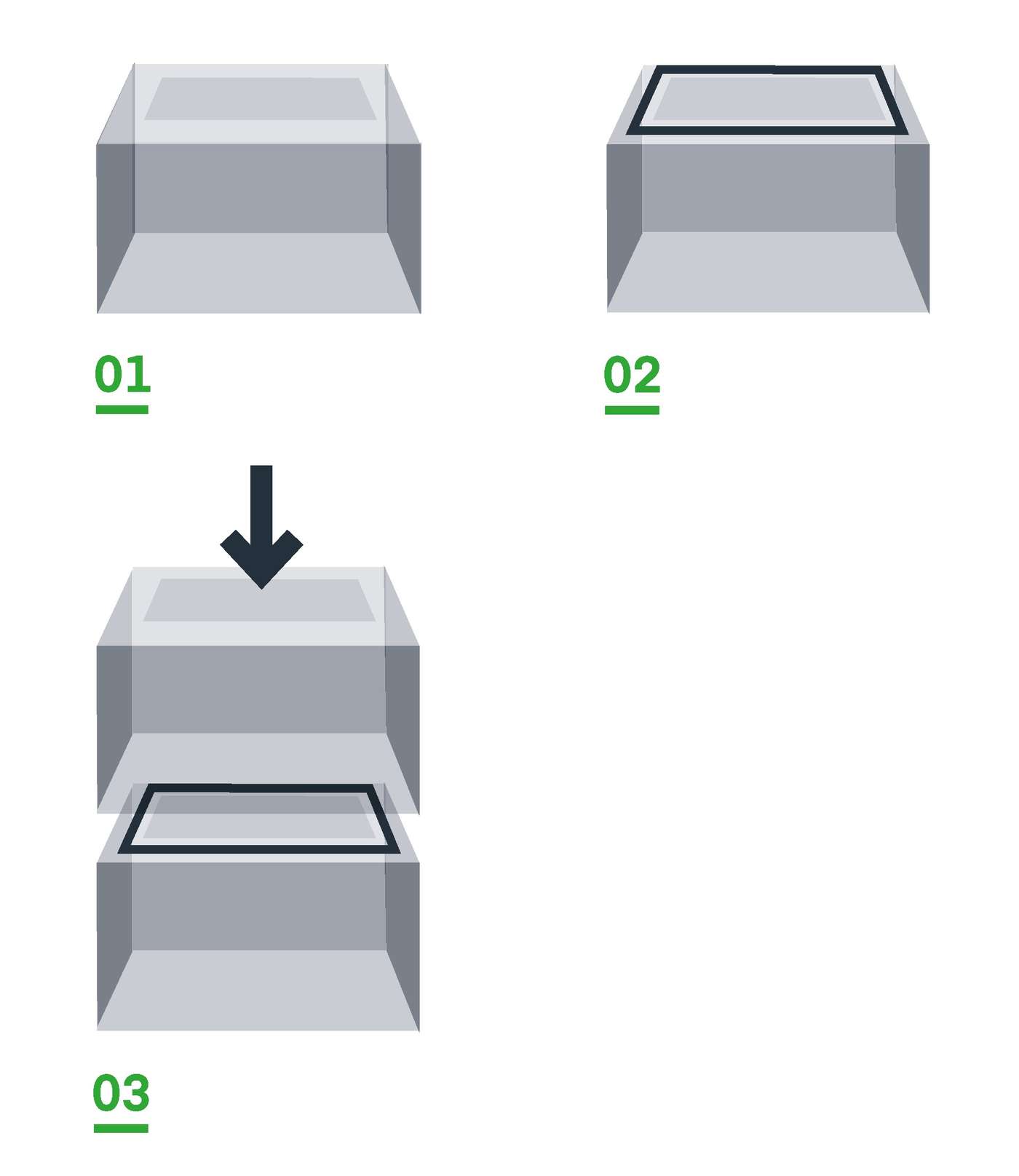

Instructions - Processing RubberElast®

Step 1

Set precast concrete element.

Step 2

Apply RubberElast® to the component to be sealed (substrate must be free of dirt, grease and oil).

Step 3

Place precast concrete component (press components together for vertical joints), compressing RubberElast® by 80%.

InnoElast® – Subsequent sealing of manholes

Civil engineering structures can be subsequently sealed or rehabilitated with InnoElast® Type 2. When sealing frame culverts and manholes with InnoElast® Type 2 at the end of the day, it is important to remove dirt and grease residues from the concrete and to ensure a load-bearing substrate to which the sealing material can adhere well. The pasty InnoElast® Type 2 is injected into the joint for sealing, where it hardens into a rubber-like material and thus seals the joint.

Sealing the maintenance / inspection manhole

Inspection chambers, also called control or access chambers, must also be maintained regularly and, if necessary, serviced with InnoElast® Type 2. They are part of the municipal wastewater supply. On a private property, within the given property boundary, these manholes represent important access points through which various pipelines coming from the house are joined in order to bridge height differences and adjust the direction to the local connection of the sewer system.

Advantages of InnoElast®:

- Solvent-free and low shrinkage

- Applicable on damp substrates from -3°C

- Weather and UV resistant, high resistance to chemicals

- Permanently elastic

- Up to 10% motion absorption

- Applicable without primer

- Pressure waterproof up to 0,48 bar

Application:

Using a tubular bag gun, InnoElast® Type 2 is applied to a clean substrate and then cures effectively. The skin formation time is between 2 and 3 hours (type 1) and 15 minutes (type 2) at a room temperature of 23°C and humidity of 50%, the curing time is 3mm in 24 hours. A primer is not required beforehand. However, it is recommended to insert a joint filler cord and tape the edges. Pressing and smoothing creates a strong bond with the joint edges.

Instructions - Processing as a joint sealant

Our tips and tricks

Before you start the work, you should check what caused the problems in the manhole. It is advantageous if the manhole wall is thoroughly cleaned with a high-pressure cleaner. If it turns out that the manhole is rooted, you must first remove any roots, thus preventing the recurrence of such damage.

For a detailed description of the processing of the RubberElast® and InnoElast® Type 2 products, please consult the technical data sheets.

RubberElast® and InnoElast® Type 2 are permanently elastic sealings. Both are characterized by their high resistance, for example, in waste water. Mounting plates or mortar upstands can be used to support loads, for example, in trafficked manholes sealed with RubberElast®.