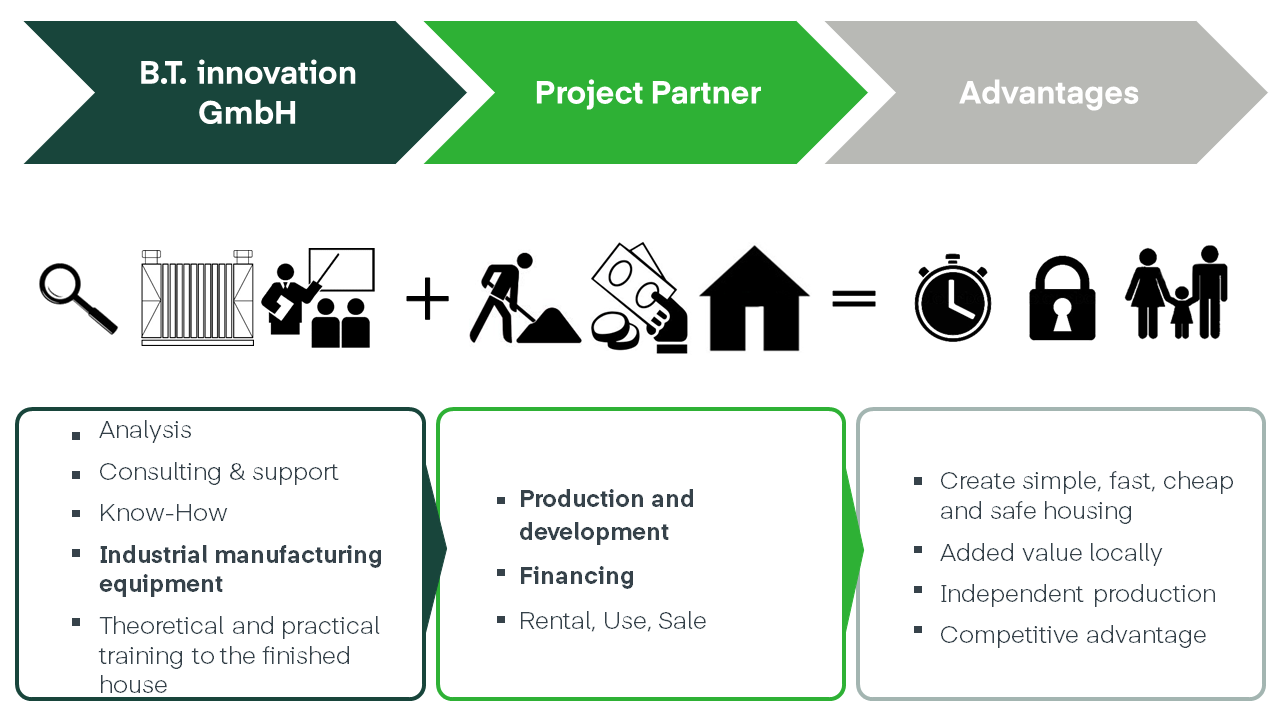

Concept for affordable housing to reduce the housing shortage in crisis areas

References

Videos

Do you have any questions?

Documents & Data Sheets

What does this product have to offer?

The “Low Cost House” concept is the solution for fast-growing and poor population groups that need high-quality housing. In just a short time, massive concrete houses can be made available to house people in need. The “Butterfly Battery®” production technology developed by BT innovation makes this possible – a formwork system for the fast and efficient production of precast concrete elements.

Your advantages

- solid concrete house

- Set-up time 2 hours

- (Almost) location-independent production

- industrial mass production

- standardised technologies

- short familiarization

Product details

For governments and aid organisations that are confronted with large numbers of refugees in crisis areas or need safe accommodation for the population after natural disasters, the “Low Cost House” concept is an ideal solution. The creation of safe, stable and cost-effective living and utility space can be achieved in just two hours with the Low Cost House.

The Low-Cost House concept at a glance

- 36m² base area

- Four rooms incl. Bathroom with shower and WC

- Space for 4-8 people

- Sockets, light switches

- Water connection in bathroom and kitchen

Power spectrum (standard version)

The construction of a 36 m² turnkey concrete house with two bedrooms, living area, kitchen and toilet can be realised in just two hours. BT innovation’s simple building concept makes this possible.

Manufacturing process

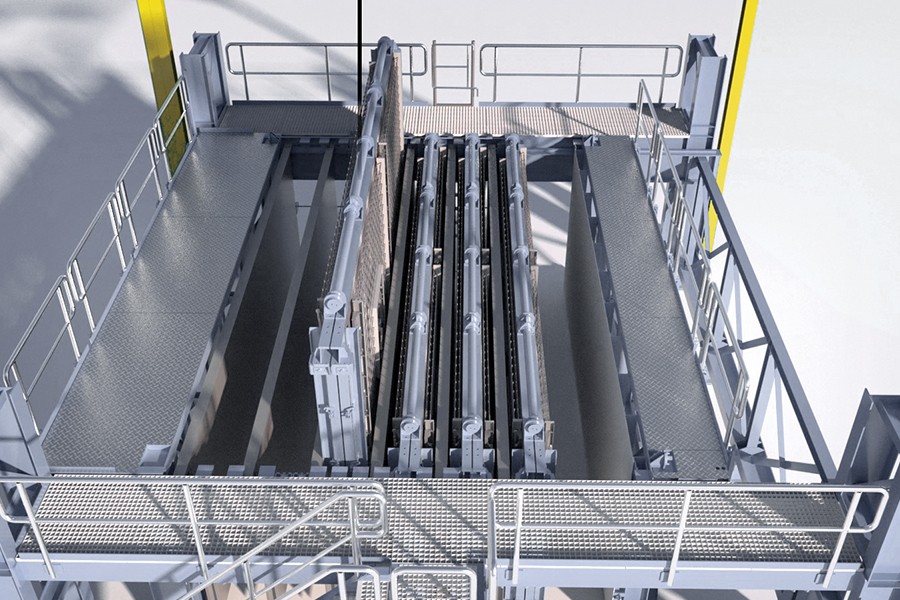

The precast concrete elements for a low-cost house are produced using the Butterfly Battery® Mould developed by BT innovation.

The manufacturing form has the following advantages over conventional technologies:

- Faster and simpler manufacturing process

- High productivity with a relatively small footprint

- No more curing of the elements necessary due to five-sided formwork-smooth concrete surfaces

Success factors in the implementation of the “Low Cost House” project are our technical know-how, as well as the technical equipment itself. Under the expert guidance of BT innovation, local workers are to learn how to use the equipment. For this, they are instructed and trained in the production of the concrete elements and the assembly of the prefabricated houses. In this way, jobs are created in the target regions, regional value chains are strengthened, and project acceptance is improved.

For more technical information about our Butterfly Battery®, please visit the product page.

Production principle

The precast elements are to be designed in such a way that an extremely high degree of prefabrication can be achieved. Preferably, the individual concrete elements are prepared to such an extent that a house is ready for occupancy immediately after the individual parts have been assembled and no or only little finishing and finishing work is required. For this, it is envisaged that:

- Wall, ceiling and roof surfaces can be provided with a complete surface finish on the outside and inside. The use of colour pigments, additives or special formulations means that finishing work such as plastering, painting, tiling or wallpapering can be dispensed with.

- The basic installations for electricity, water and sewage are already completely prepared, so that the buildings only need to be connected to the corresponding networks (if available) during assembly.

- The usual supply routes for the target region, e.g. water and sewage tanks, are already taken into account in the building design.

In particular, alternative and sustainable supply options can also be considered, e.g.:

- A roof drainage system that collects rainwater and directs it into appropriate cisterns for later use as drinking or service water.

- An energetic supply of the house via solar energy, which can later be used for electricity, heating and cooling purposes.

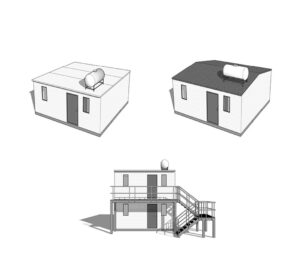

Design

Depending on the region and demand, different roof types can be realised. On the one hand there is the flat roof variant (standard) and on the other hand the variant with the classic gable roof. With the help of the flat roof variant, it is possible to implement multi-storey arrangements with external stairs or semi-detached house variants.

In principle, BT innovation is able to adapt production according to customer requirements. By default, however, the “low cost house” concept will be offered with a floor area of 36 m².

Connection of the precast concrete elements

In order to be able to realise the short construction time of only 2 hours, so-called “dry” connection techniques are used. The BT-Spannschloss® developed by B.T. innovation GmbH is suitable for this purpose. It enables easy and precise connection of the individual precast concrete elements. No other tools are necessary for the connection. A lot of time and costs are saved this way. After assembly, the BT-Spannschloss® is immediately fully and permanently loadable. For the BT-Spannschloss®, which is already established on the market, the general building authority approval was granted by the Deutsches Institut für Bautechnik.

Sealing of the precast concrete elements

To protect the house from water, dust and insect penetration, we recommend RubberElast® joint tape, developed for dry jointing techniques. It is extremely easy to use and almost temperature-independent. The material is securely bonded to the concrete elements by the contact pressure and yet remains permanently elastic. The test certificate of the Braunschweig Materials Testing Institute is available for RubberElast®.

Our waterproofing portfolio is complemented by the flexible InnoElast®. It seals movement and connection joints indoors and outdoors securely and permanently and has a test certificate from the Materialprüfungsamt North Rhine-Westphalia.

Transport

The elements are transported, for example, with the help of an inloader pallet modified by B.T. Transport of all house elements is possible on this pallet. The advantage of this technology is that the elements are loaded directly onto the load carrier changing system. This avoids cost-intensive reloading work and expensive downtimes for the truck.

Building material

The basic building material for the house is concrete. Concrete is one of the most widely used building materials in the world, and can therefore be produced almost everywhere in reasonable qualities with locally available raw materials. It is easy to work with and can be shaped into almost any form. Concrete has good structural-physical properties, is very resistant and is therefore ideally suited for solid, durable structures.