Construction Formwork for Curves and Edges for the use with In-situ Concrete

References

Videos

Do you have any questions?

Documents & Data Sheets

What does this product have to offer?

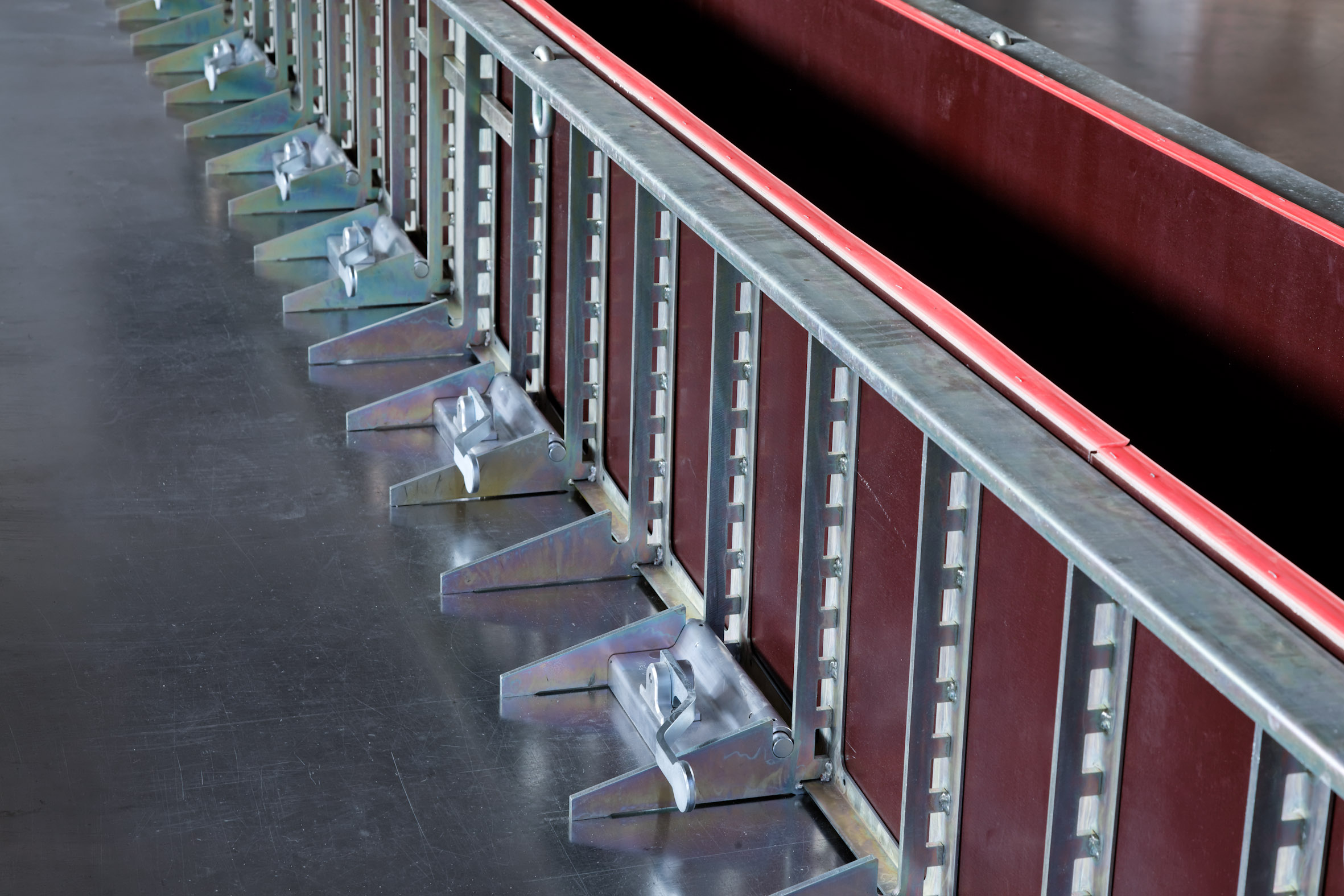

With the flexible formwork system, straight lines, curves and corners can be created with ease. Syflex® is the optimal solution for base slab, edge and strip foundation formwork.

Your advantages

- Very high reusability (cost minimisation)

- Quick assembly and disassembly (time saving)

- super light elastic material

- Individual shaping through cutting

- quick amortisation

Product details

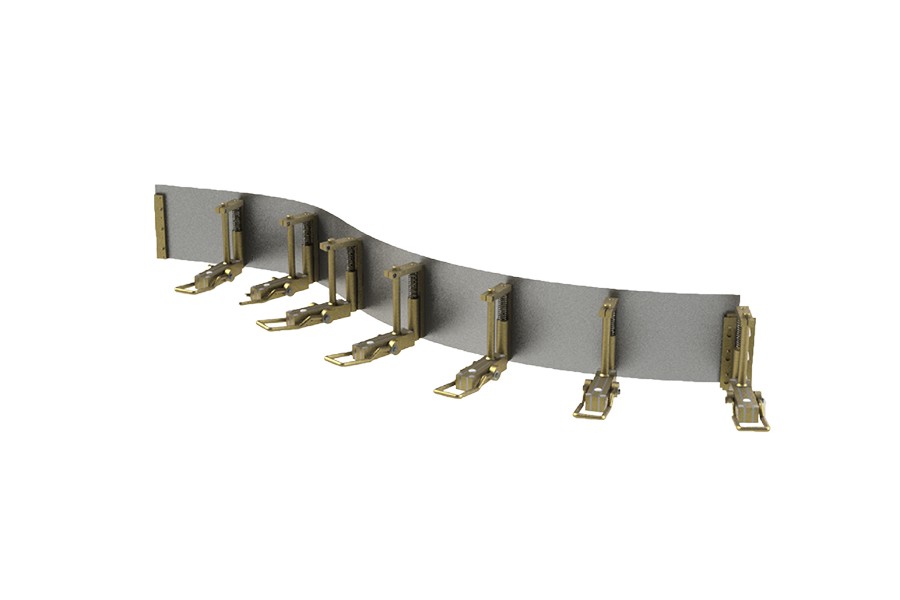

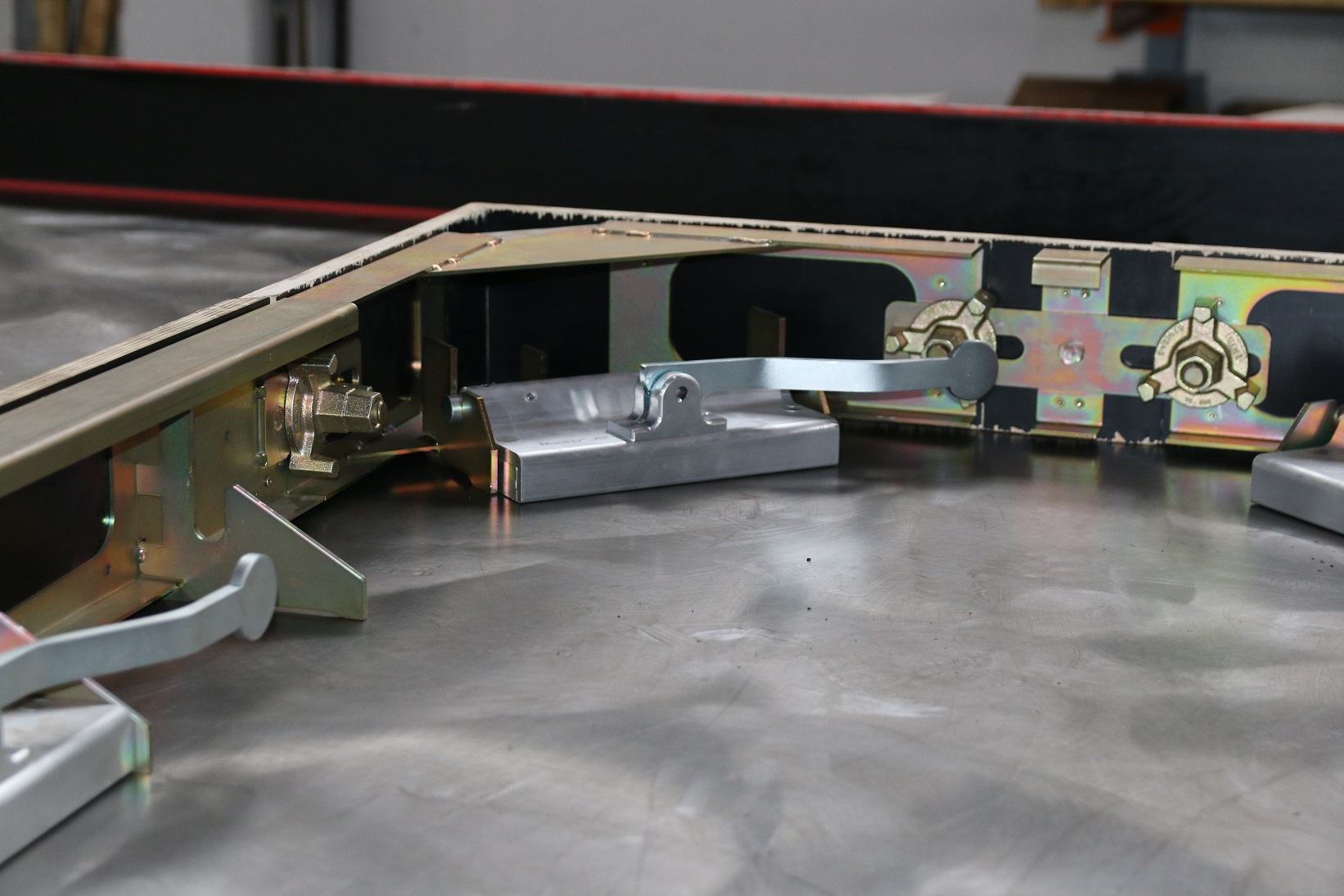

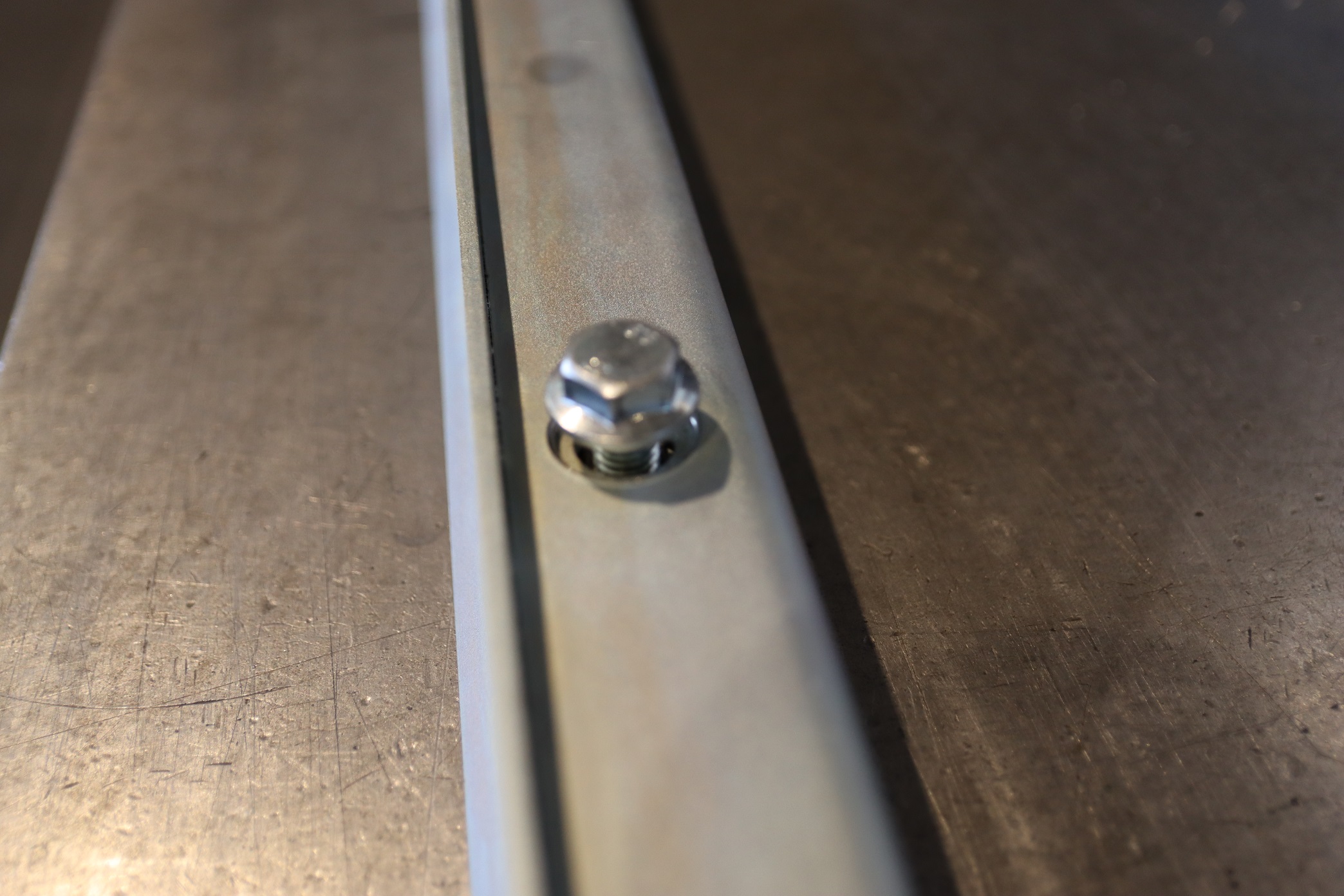

The Syflex system consists of a formwork plank and a system eccentric, via which it can be quickly attached to or detached from a support (soil nail or similar). It is made of a special plastic, which makes it very flexible and light. Due to the material properties, Syflex is ideally suited for curves, corners but also simple straight lines. You can watch the application of the Syflex® system in the product video.

Profile cavities provide additional lightness and allow two planks to be connected via a plug-in system. The smooth surface and flexibility of the formwork beams also make it reusable several times.

Fields of application of Syflex®

- Base slab, edge and strip foundation formwork

- Slab edge and ring beam formwork

- Path edgings

- Silo construction

- Roundabouts

Questions and answers about the product

1. what are the dimensions of the Syflex® formwork elements?

The Syflex® formwork elements have a length of 5 m and can be cut to size on site. They are available in heights of 100 mm, 150 mm, 200 mm, 250 mm and 300 mm. With the Syflex® formwork elements, total formwork heights of up to one metre can be implemented.

2. which radii can be represented with the help of Syflex®?

With Syflex® radii of 2 m and more can be realised.

3. what accessories and tools are needed?

Earth nails or formwork trestles (earth nails up to 30 cm formwork height, then formwork trestles), Syflex® system eccentric, plastic pipes for connecting the formwork elements, hand-held circular saw or table saw, cordless screwdriver and screws.

4. what distance must the stiffeners have?

The spacing of the bracing depends on the total height of the formwork and its maximum permissible deflection during concreting. You will find an overview in the technical data sheet of the product. (page 2)