Joint tape for secure and pressure-proof structural joint sealing - RubberElast®

References

Videos

Do you have any questions?

Documents & Data Sheets

What does this product have to offer?

RubberElast® is a self-adhesive, tried-and-tested squeeze joint tape for the secure and pressure-tight sealing of component joints between precast elements.

Your advantages

- Water pressure-tight up to 0.5 bar

- Processing from -10°C to +40°C

- No swelling on contact with water

- Weather, acid, alkali and salt resistant

- Immediately watertight after installation

- Permanently elastic

Product details

The self-adhesive sealing tape RubberElast® seals component joints in canal and civil engineering and in hydraulic structures, among others. The joint sealant retains its elasticity even at low temperatures and is resistant to weathering, acids, alkalis and salt.

RubberElast® can be processed quickly and without further aids. It is self-adhesive and is glued to one side of a component surface. The precast parts are then assembled and the RubberElast® is compressed in the component joint so that the component joint is filled. The joint is immediately watertight after grouting. If prefabricated walls are installed, the use of the BT turnbuckle is recommended. The combination of RubberElast® with the BT turnbuckle® is particularly proven in flood protection.

The material remains permanently elastic and thus seals the joints permanently. Installation should be carried out in the temperature range from -10 °C to +40 °C. RubberElast® retains its elasticity even at low temperatures. In addition to its very good adhesion to concrete, the squeeze waterstop also has other excellent adhesion properties, such as to metals, glass and other materials.

The sealing tape is used for hydraulic structures, in canal and civil engineering and in residential and commercial construction.

You can watch the application of RubberElast® in the product video.

Areas of application for RubberElast®

- Hydraulic structures (e.g. angle retaining walls in flood protection)

- Sewer & civil engineering (e.g. manholes, media channels, amphibian tunnels), multi-storey

- Residential & commercial construction (e.g. WU basement, white tank)

When using RubberElast® for sealing precast concrete joints on building components made of water-impermeable concrete, in accordance with the “WU Guideline”, the general test certificate issued by the building authorities must also be observed.

Technical information

The substrate must be dry during installation. For difficult substrates, the additional use of RubberElast® primer is recommended.

- Colour: Black

- Consistency: elastoplastic

- Processing form : self-adhesive on rolls with protective film

- Spec. Density : Approx. 1.3 g/cm3

- Tensile bond strength : > 60 kPa (on concrete)

- Max. Joint displacement : Up to 7 mm for sizes 38 x 32, 48 x 42 Up to 3 mm for sizes 32 x 25, 25 x 19, 17 x 17

- Temperature resistance : -40°C to +60°C

- Working temperature : -10°C to +40°C at component and material temperature

- Chemical resistance : H2SO4(pH 4) acid, liquid attacking concrete Ca(OH)2(pH 12) alkali, NaCI salt

Application for professional sealing

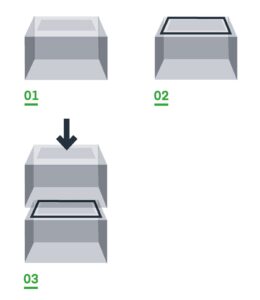

- 01 Set precast concrete element

- 02 Apply RubberElast® to the component to be sealed (the substrate must be free of dirt, grease and oil).

- 03 Place the precast concrete element (press the components together for vertical joints) and compress RubberElast® by 80%.

Questions and answers about the product

1. Do the joints need to be cleaned?

Yes, the joint flanks must be dry and free of dust, grease, loose components and other separating materials.

2. Do I need to apply a primer to make RubberElast® last?

It depends on the type of surface. RubberElast® is always applied without primer. If the RubberElast® does not adhere to the substrate, an additional primer can be used.

Which RubberElast® size do I use for my project?

The choice of the right RubberElast® size determines the width of the joint edge and the final joint width. The RubberElast® is squeezed into the joint and compressed to 20% of its original size. This means that the material presses sideways into the joint. If the joint flank is too narrow, the RubberElast® is pressed out of the joint. If the joint width is too large or too small, the sealing effect cannot be achieved. Let our staff give you expert advice on this. We would also be happy to send you our table for selecting the right size.

4. when can RubberElast® be loaded with water pressure?

It does not react chemically with other substances but, once properly compressed, can withstand water pressure.

5. how much force do I need to apply to compress the tape?

The force to be applied depends on the selected size of the belt and the prevailing ambient temperature. To calculate the correct amount of force, please refer to the information in the technical data sheet.

Other products from the sealing technology category

En esta sección encontrará información útil sobre diversas aplicaciones y guías para distintos proyectos.