Formwork for quick and easy shuttering of precast concrete elements

References

Videos

Do you have any questions?

Documents & Data Sheets

What does this product have to offer?

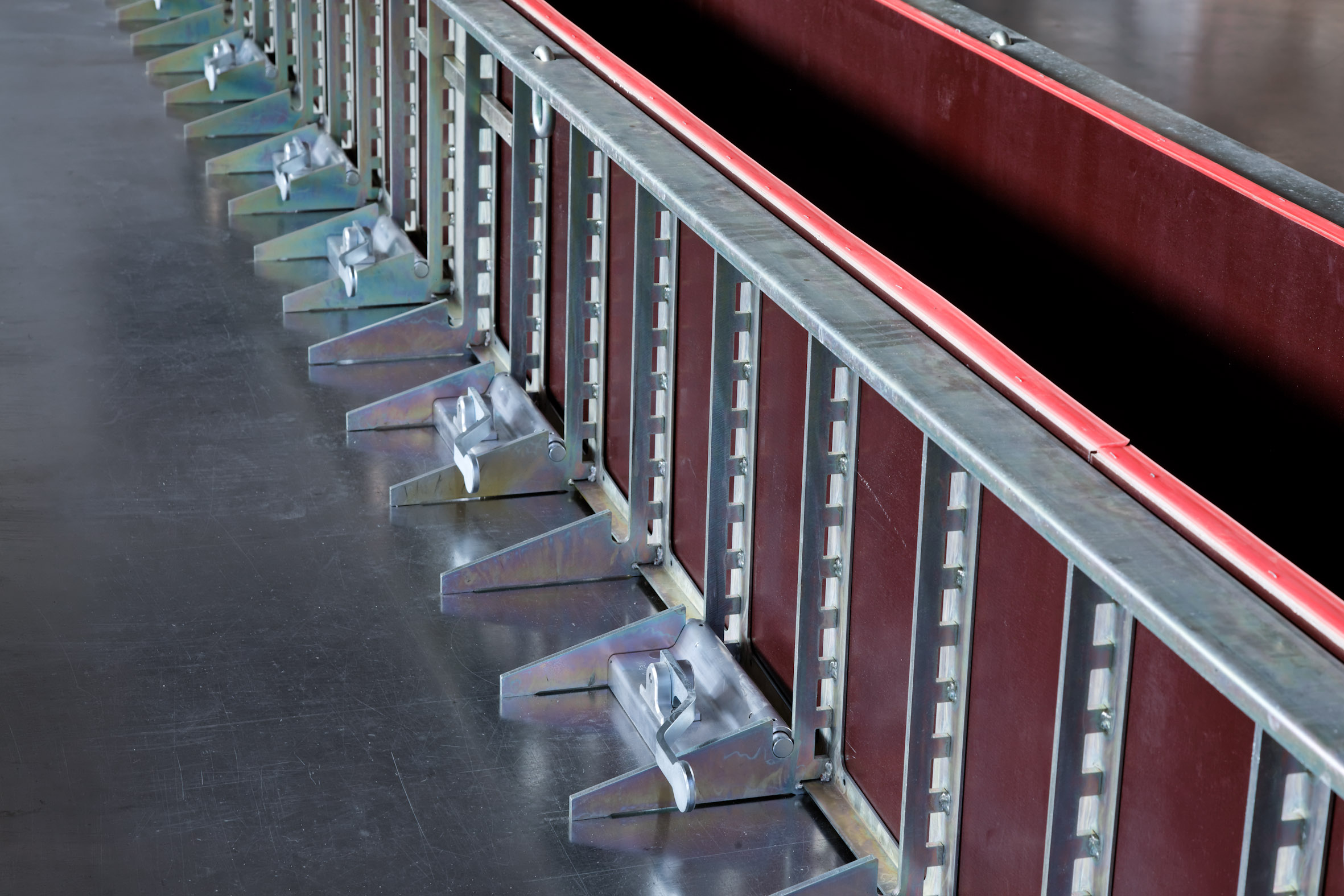

MultiForm is a robust and flexible formwork support system for the production of a wide range of precast elements.

Your advantages

- Fast and ergonomic applicability

- No sealing with silicone between formwork skin and switch table

- Stable and robust system - designed for use in the precast plant

- The window and door recess can be dismantled inwards

Product details

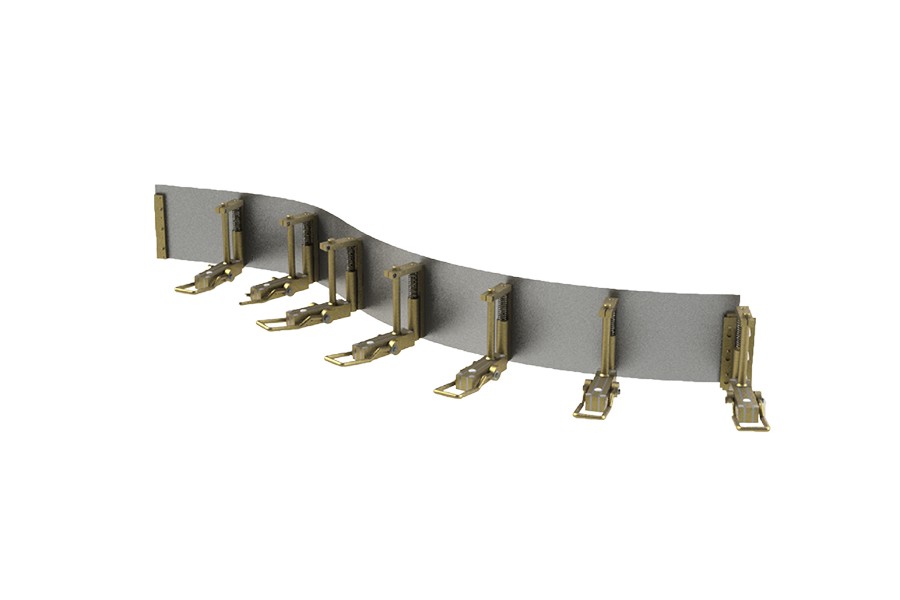

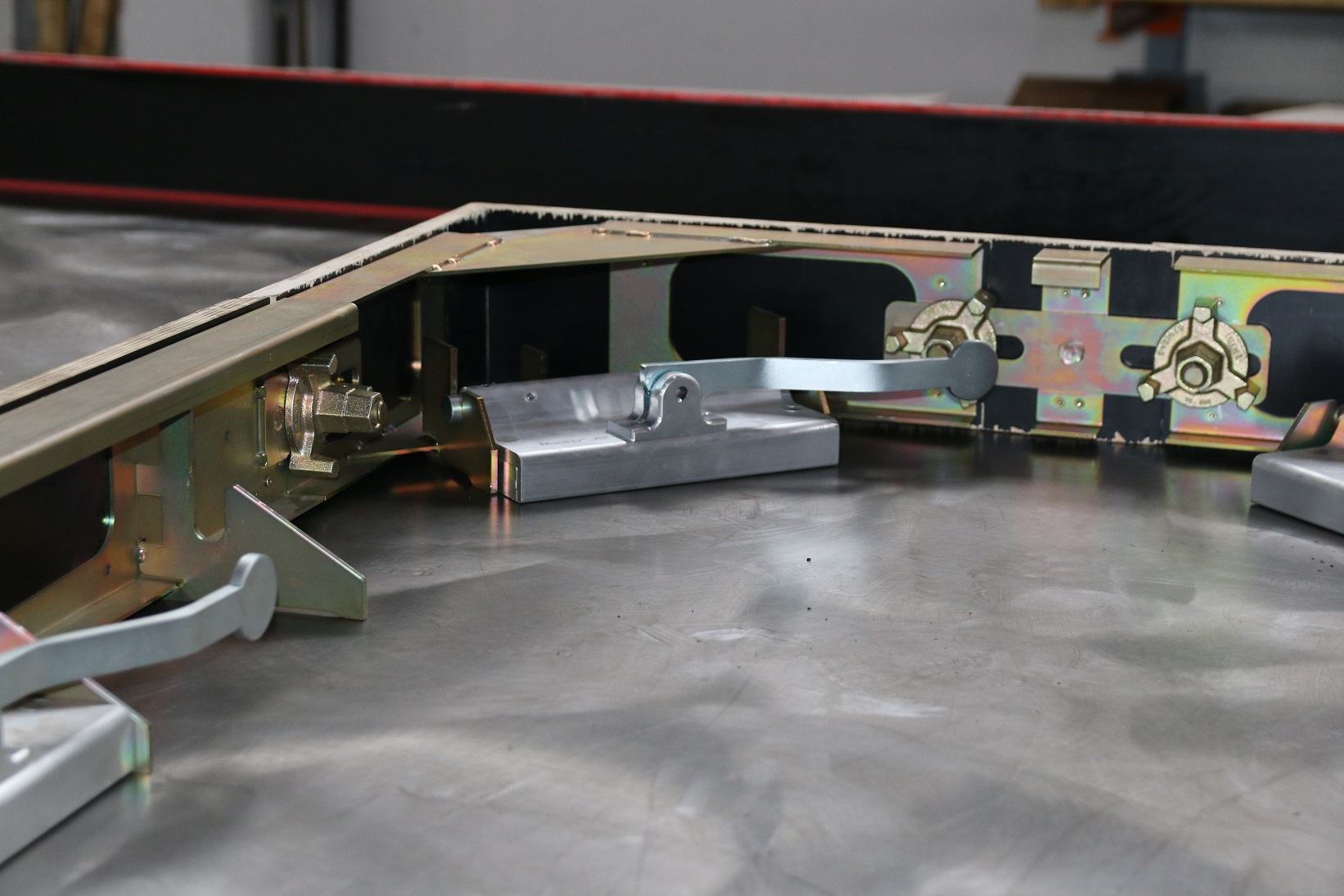

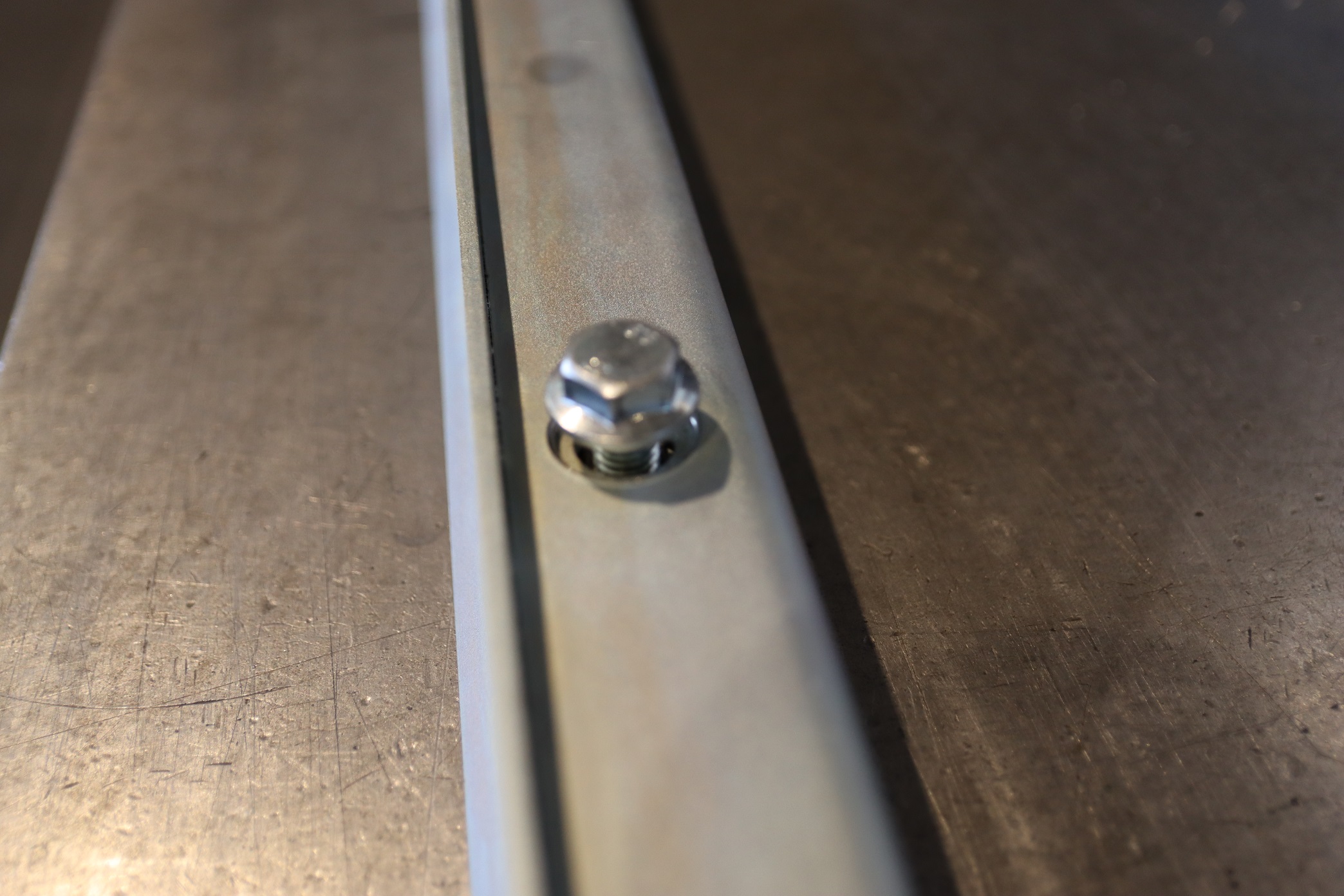

With the MagFly® magnets, MultiForm can be moved easily on the control table and positioned precisely. Since the MagFly® AP MultiForm presses onto the switch table, when using a

PE triangular strip, the joint sealed immediately when the magnet is activated. This eliminates the need for subsequent sealing with silicone.

Matching MultiForm, the window and door recess offers a clever solution for enclosed openings in the concrete part. With elements that can be dismantled inwards, the formwork can be stripped non-destructively and thus reusable. The integrated receptacle for the MagFly® magnets enables fast and precise assembly and disassembly of the formwork. You can watch the application of the MultiForm in the product video.

Areas of application of the MultiForm

- Production of solid and sandwich walls

- Manufacture of platform slabs, supports and beams

- Use on tilt table, shuttering table, circulation pallets and wooden surfaces

Instructions for proper use

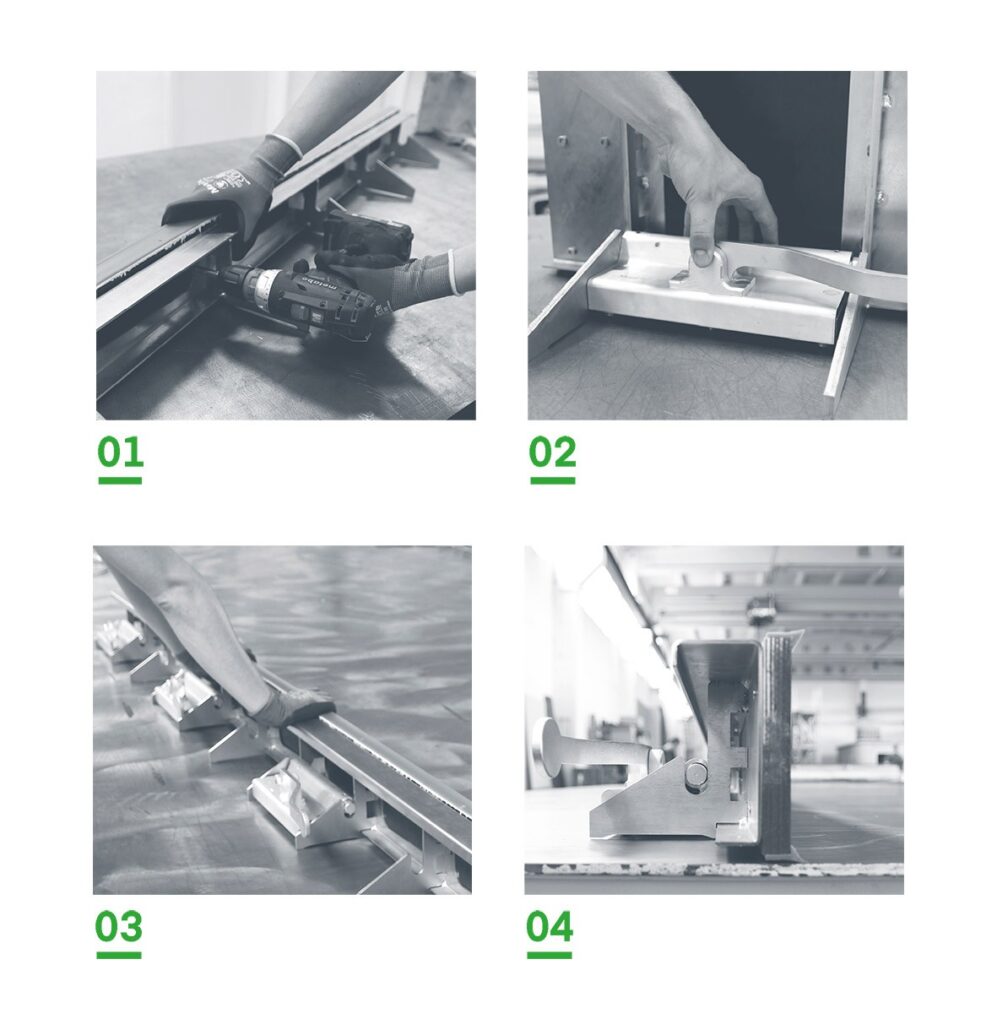

- Place the formwork facing in front of the MultiForm shuttering system and fix it with screws.

- MagFly® magnets are used in MultiForm

- Move and place the formwork on the formwork table

- Fixing the magnets after positioning

UniForm® - reusable robust formwork facing

Advantages:

- Stable and robust system - designed for use in the precast plant

- Long-term quality improvement

- High reusability

- permanent material saving

- Fast and flexible applicability

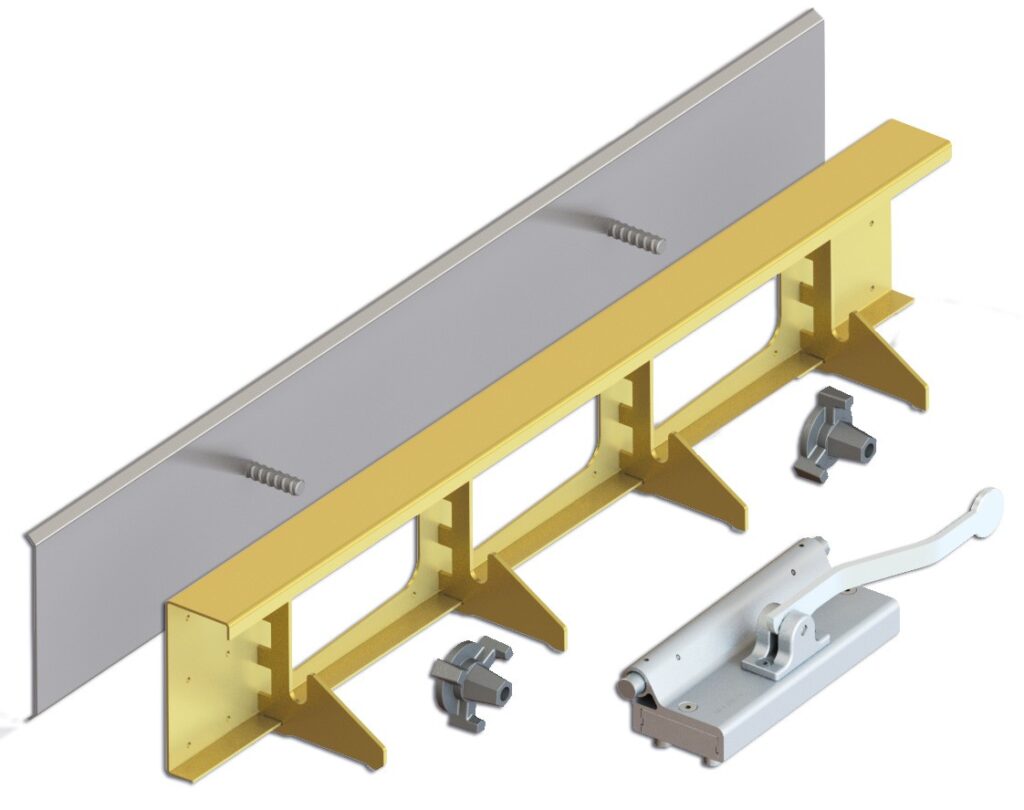

UniForm® is a permanent steel formwork facing for fixing to MultiForm type 2.

The UniForm® formwork offers extremely high material resistance. Sawing, screwing on and throwing away worn formwork strips is a thing of the past with UniForm® formwork sheets. The quality of the switched elements can be increased in the long term, among other things, through cleaner and straighter bevel formations on the element. A chamfer on the top and / or bottom side of the sheet is possible upon customer request.

Multiple reuse goes hand in hand with flexibility thanks to a simple attachment system compatible with the MultiForm Type 2. The permanent steel formlining is bolted to the MultiForm Type 2 using Dywidag rods attached to the back according to the respective formwork height.

Questions and answers about the product

1. what formwork heights and lengths can the formwork have and are special solutions possible?

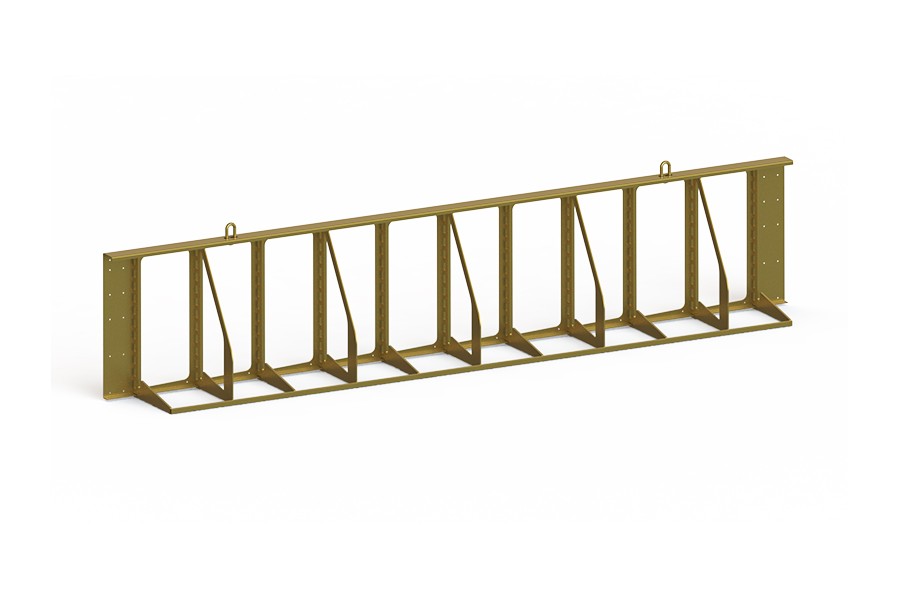

The standard length of the trays is 3025 mm, however, it is possible to customise the length of the trays if required. The MultiForm system is available in heights from 68mm and can thus be used for sound heights from 7 cm. It has already been successfully tested for formwork heights of up to 80 cm. Special solutions are also easily possible with the MultiForm. Whether angled trays or other adaptations, our production adapts the tray exactly to your needs. We will be happy to advise you on the selection of the right MultiForms for your application.

2. how do I seal the formwork so that my concrete does not “bleed”?

When using a wooden formwork facing with a PE triangular strip, it is normally not necessary to seal additionally. Due to the contact pressure of the shuttering magnets, the air gap between the shuttering table and the shuttering is automatically closed when the magnets are activated and “bleeding” is prevented.

How many magnets do I need to fix the scarf?

Our recommendation is to generally use one magnet per metre. However, this is only an approximate value, because various variables have an influence on it: the sheet thickness of the steel table, the evenness and cleanliness of the steel table, the concrete used, the element dimensions, the filling height and the production position (horizontal or vertical).

4. how can I move large MultiForm formwork?

MultiForm formwork from a height of 40 cm should preferably be moved by crane for reasons of work safety. For this reason, formers of this height are equipped with transport eyelets as standard. Alternatively, the use of a transport trolley is also possible. If it is desired that the employees can move the trays on their own, the MultiForm Alu, which is up to 70% lighter, should be used.

Is the MultiForm compatible with laser systems or shuttering robots?

Yes, the MultiForm formwork beams are compatible with laser measuring systems. Use with semi-automatic positioning aids such as formwork manipulators is also possible if required. Only the shuttering is not compatible with fully automatic shuttering robots, but our U- and H-profiles can be used for this purpose.