Aluminium Shuttering for Precast Concrete Walls and Panels made of Anodised Aluminium

References

Videos

Do you have any questions?

Documents & Data Sheets

What does this product have to offer?

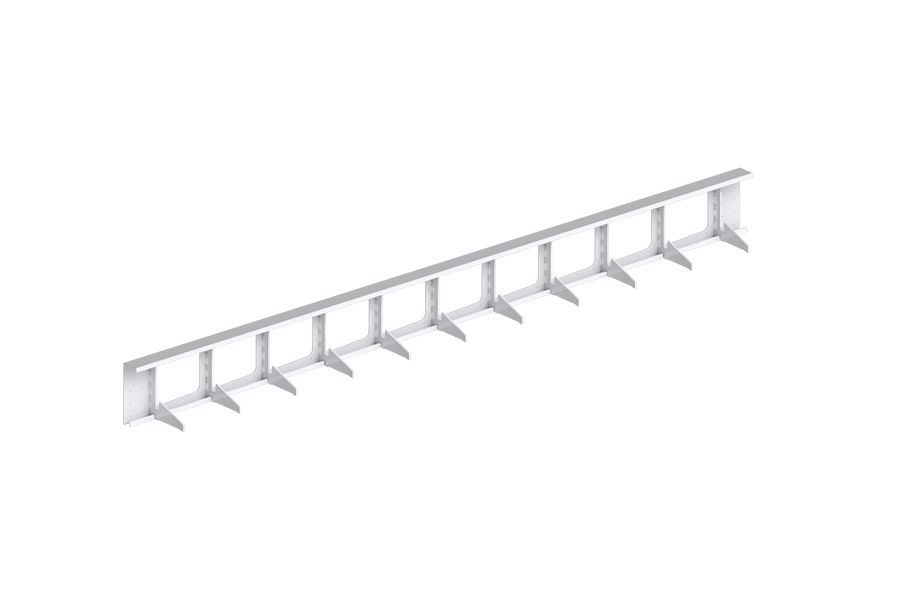

MultiForm Alu is a lightweight, but dimensionally stable and sturdy formwork beam made of specially coated aluminium.

Your advantages

- Up to 70% lighter than other steel formwork beam systems

- Dimensionally stable and robust thanks to new design

- Conforms to the German Load Handling Ordinance

- Dispensing with crane systems, transport with fewer personnel

- Conforms to the German Load Handling Ordinance

- Rapid amortisation through synergies in production

- No time-consuming additional sealing, e.g. with silicone

Product details

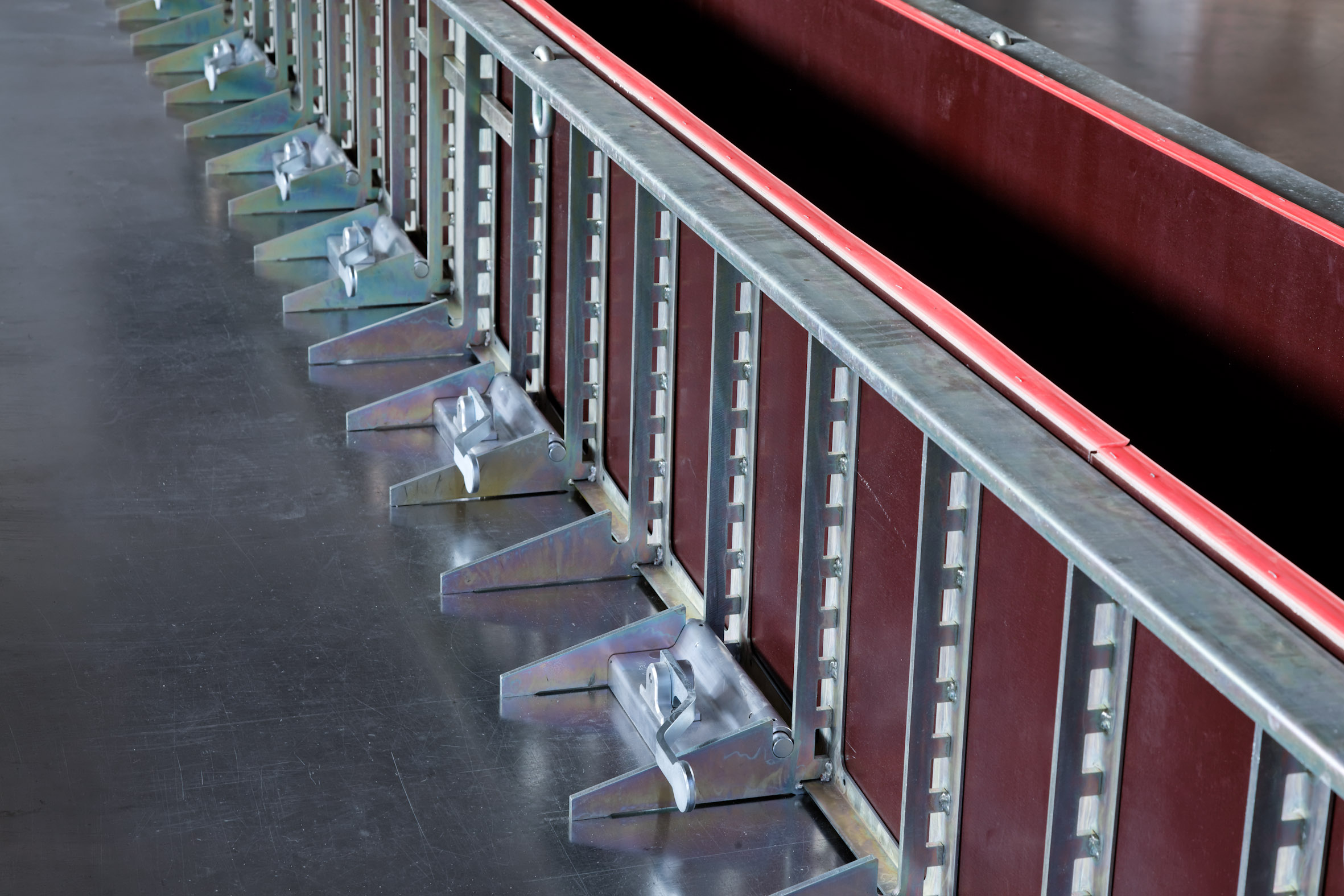

Due to the reduced dead weight, MultiForm Alu weighs less than half compared to other beam systems, even with the formwork timber mounted. In this way, the MultiForm Alu not only ensures conformity with the German Load Handling Ordinance for all formwork heights, but also significantly reduces the amount of work involved in shuttering and striking. Even formwork with 400 mm formwork height incl. Timber can be transposed by a member of staff. In addition, the load reduction is an important relief for the employees and an adaptation to the ageing workforce. It has a positive effect on sick leave and fundamentally plays a central role in workplace health management.

The formwork facing made of wood, chipboard or steel panels can simply be bolted to the formwork from behind. The large openings on the back of the MultiForm Alu make it possible to attach even bulky and large built-in parts from behind. As with any MultiForm formwork, the formwork height can be adjusted by changing the formlining. Important: Even with larger formwork heights, the formwork can be assembled by hand, dismantled and carried by one person due to its low dead weight.

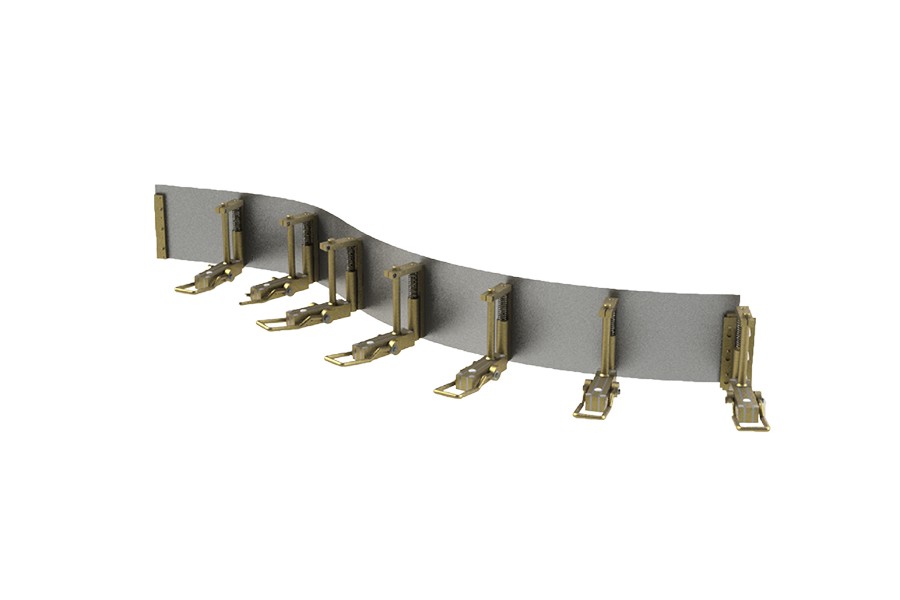

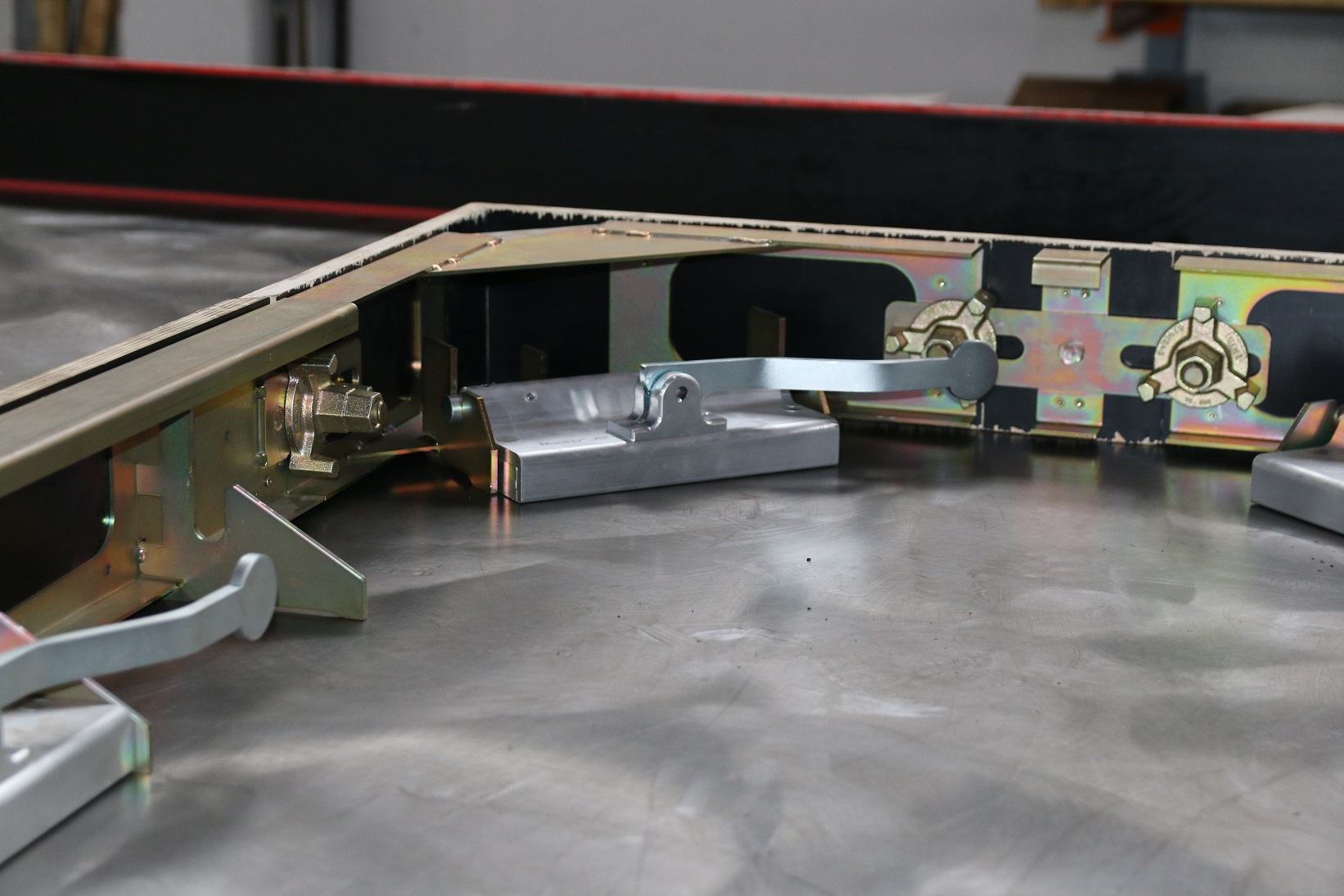

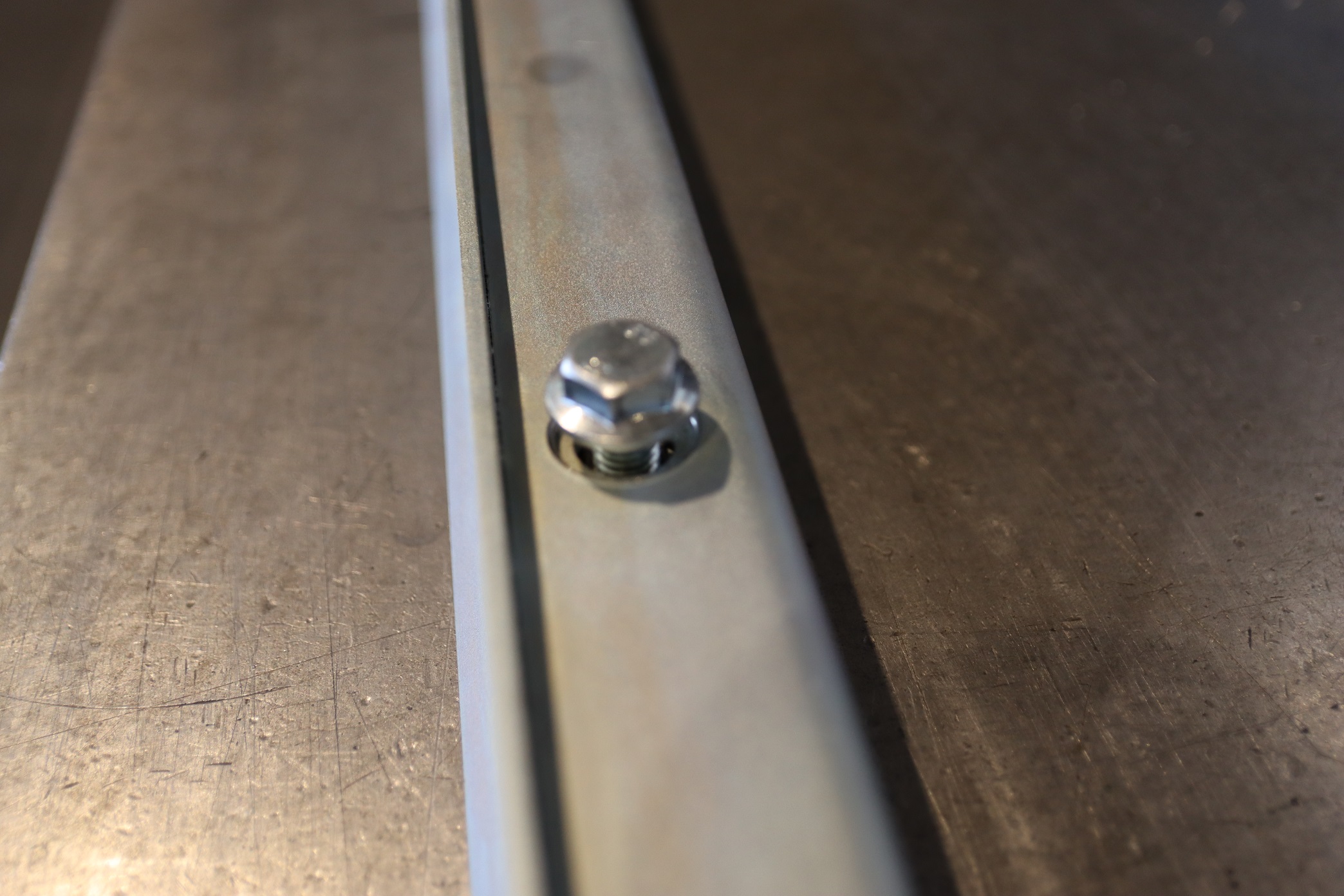

In combination with the patented MagFly® magnet, the MultiForm Alu can be easily moved on the steel surface and precisely positioned. The additional and usually costly sealing with e.g. silicones or other sealants is no longer necessary.

Areas of application for Multiform Alu

- Production of solid and sandwich walls

- Manufacture of platform slabs, supports and beams

- Use on tilt tables, indexing tables, circulation pallets and wooden surfaces

Questions and answers about the product

1. what formwork heights and lengths can the formwork have and are special solutions possible?

The standard length of the trays is 3025 mm, however, if required, the length of the trays can be adjusted individually. The MultiForm Alu system is available in heights from 68 mm and can thus be used for formwork heights from 7 cm. It has already been successfully tested for formwork heights of up to 80 cm. Special solutions are also easily possible with the MultiForm Alu. Whether angled shells or other adaptations our production adapts the shell exactly to your needs. We will be happy to advise you on the selection of the right MultiForms for your application.

2. how do I seal the formwork so that my concrete does not “bleed”?

When using a wooden formwork facing with a PE triangular strip, it is normally not necessary to seal additionally. Due to the contact pressure of the shuttering magnets, the air gap between the shuttering table and the shuttering is automatically closed when the magnets are activated and “bleeding” is prevented.

How many magnets do I need to fix the scarf?

Our recommendation is to generally use one magnet per metre. However, this is only an approximate value, as various variables have an influence on it: the sheet thickness of the steel table, the evenness and cleanliness of the steel table, the concrete used, the element dimensions, the filling height, the production position (horizontal or vertical), ….

How do I connect two bowls together?

If two MultiForm formwork panels are to be joined together, the formwork panel is overlapped and screwed on normally from behind. The formers are then joined and ready for production. With the standard length of 3,025 mm, the magnetic pockets are distributed in such a way that both shells can be connected at the joint by means of a magnet.

Is the MultiForm compatible with laser systems or shuttering robots?

Yes, the MultiForm formwork beams are compatible with laser measuring systems. Use with semi-automatic positioning aids such as formwork manipulators is also possible if required. Only the shuttering is not compatible with fully automatic shuttering robots, but our U- and H-profiles can be used for this purpose.