Magnet for quick and easy shuttering of precast concrete elements

References

Videos

Do you have any questions?

Documents & Data Sheets

What does this product have to offer?

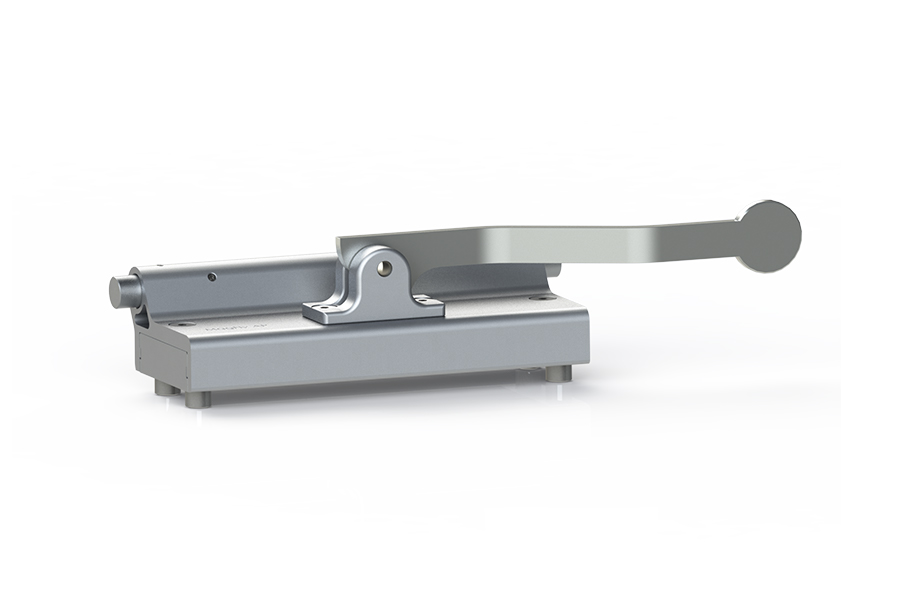

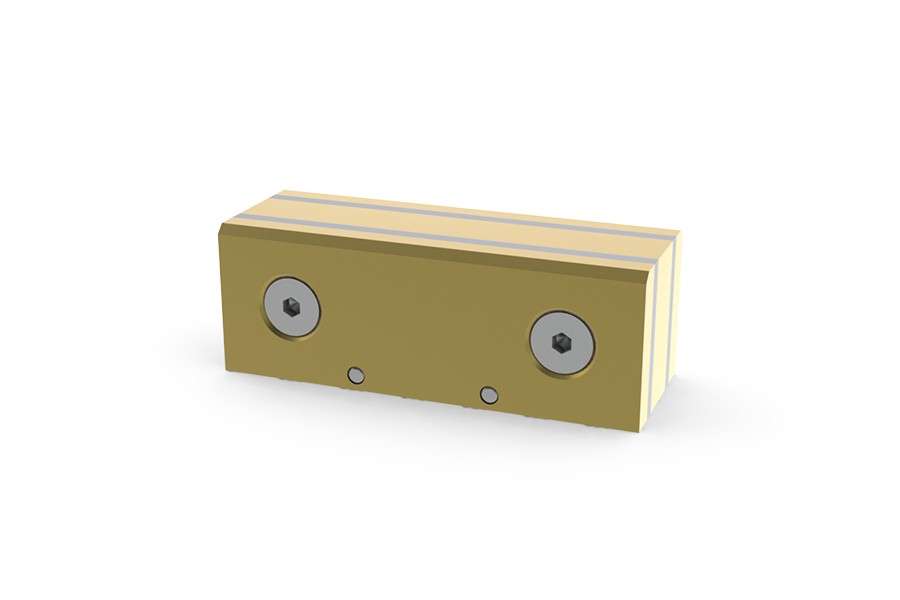

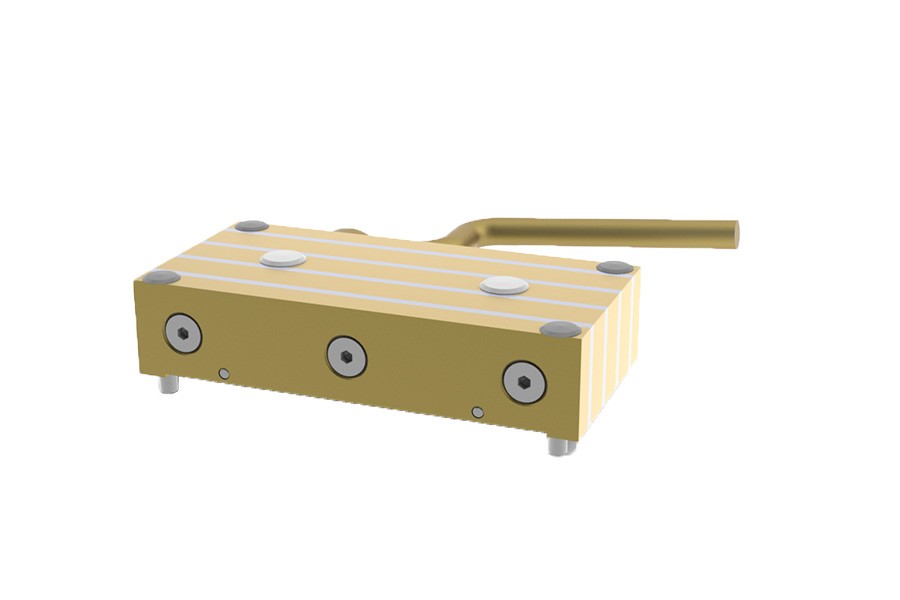

The MagFly® AP is a patented shuttering magnet and part of the BT shuttering system. Its adhesive force to mass ratio is unique, as is the unique foot/spring system that allows the magnet to glide effortlessly over the formwork table.

Your advantages

- Best adhesive force / mass ratio worldwide 22.000N / 5,6kg

- Improved handling: release force now only 37 pounds.!

- Extremely light. One employee can carry 4 magnets at the same time!

- Millimetre-precise positioning thanks to patented MagFly® technology

- Precise fixing of the magnet by light hand pressure

- Patented hold-down of the formwork, thus high contact pressure of the formwork on the formwork table

- No silicone necessary for sealing

- Easy and ergonomic handling due to foot/spring system

- Magnet perfectly matched to formwork beams

Product details

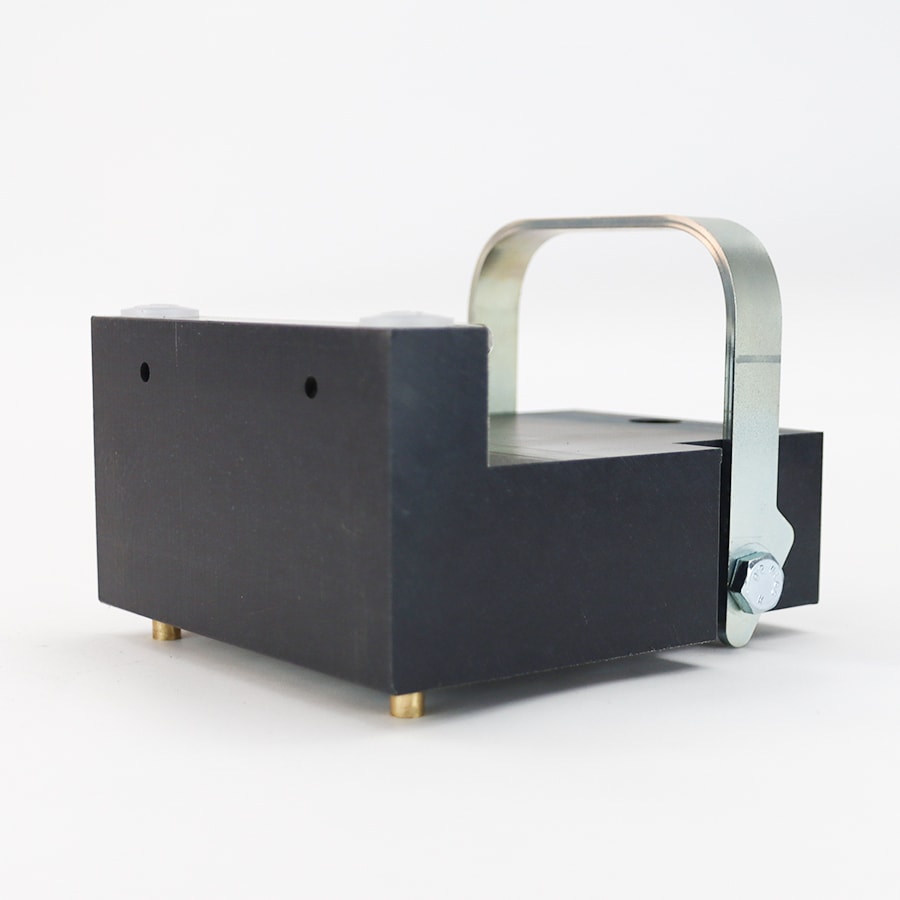

Firm pressure from above on the magnet activates it, and its magnetic force causes it to adhere to the formwork table. With the integrated lever, the MagFly® AP can be easily and quickly released and realigned. The MagFly® AP does not require any additional tools or adapters to use it.

The ultra-light aluminium housing enables ergonomic working with the magnet and protects the user’s strength. In combination with the MultiForm formwork beams and an attached plastic triangular strip, the formwork beam and the triangular strip are pressed firmly onto the formwork table when the magnet is activated, so that subsequent sealing of the edge with silicone is simply not necessary. These effective technologies are perfectly coordinated with each other and thus considerably accelerate the production of precast concrete elements. You can watch the application of the MagFly® AP in the product video.

Fields of application of the MagFly® AP

- Shuttering magnet for pallet circulation systems as well as tilting tables

- Formwork for walls, columns etc.

How powerful is the MagFly® AP?

The MagFly® AP has an adhesive force of 22,000 N at a weight of only 5.6 kg. This gives it a first-class adhesion force/mass ratio. For more powerful magnets, you can fall back on the MagFly® universal magnet, which is available up to an adhesive force of 30,000 N.

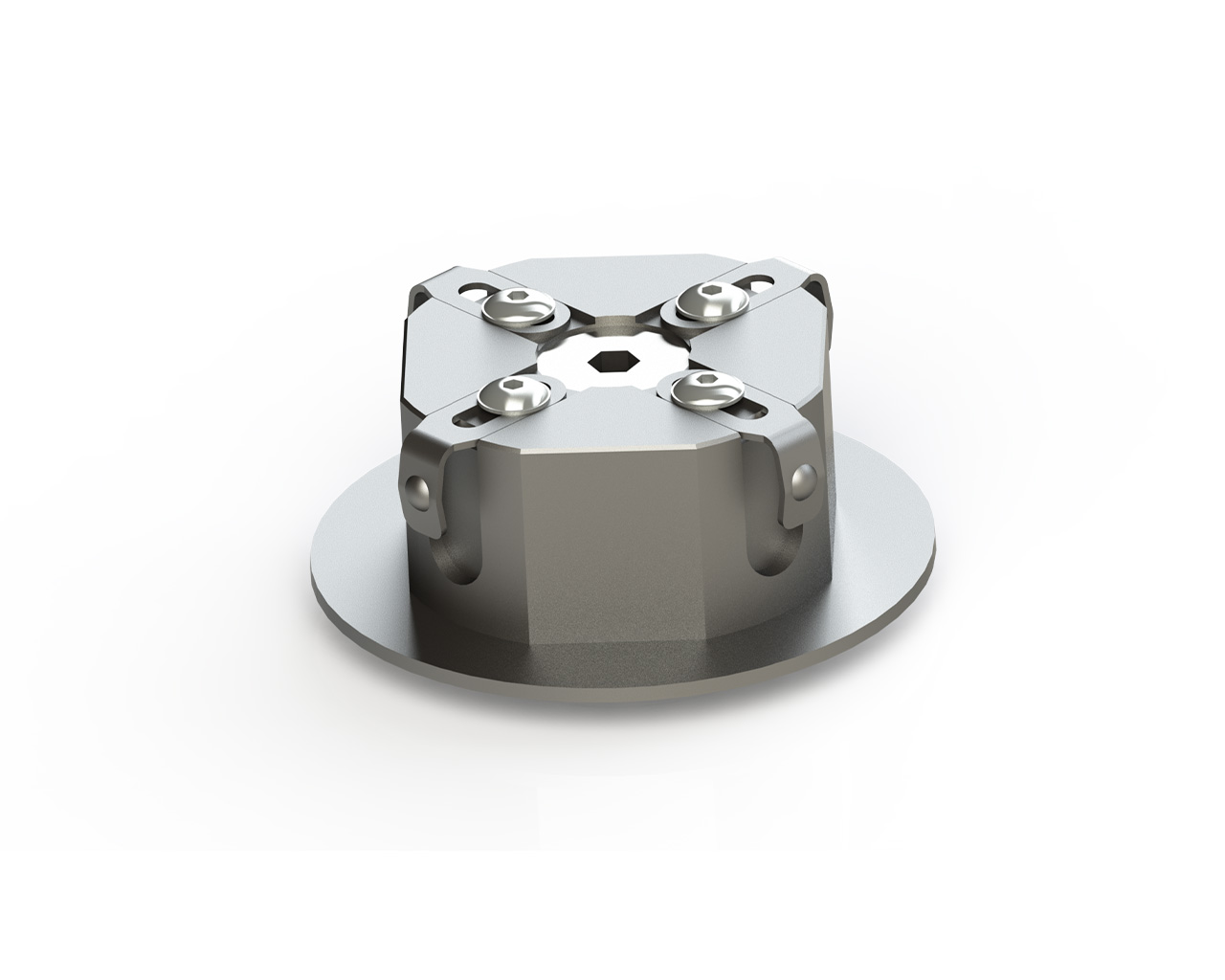

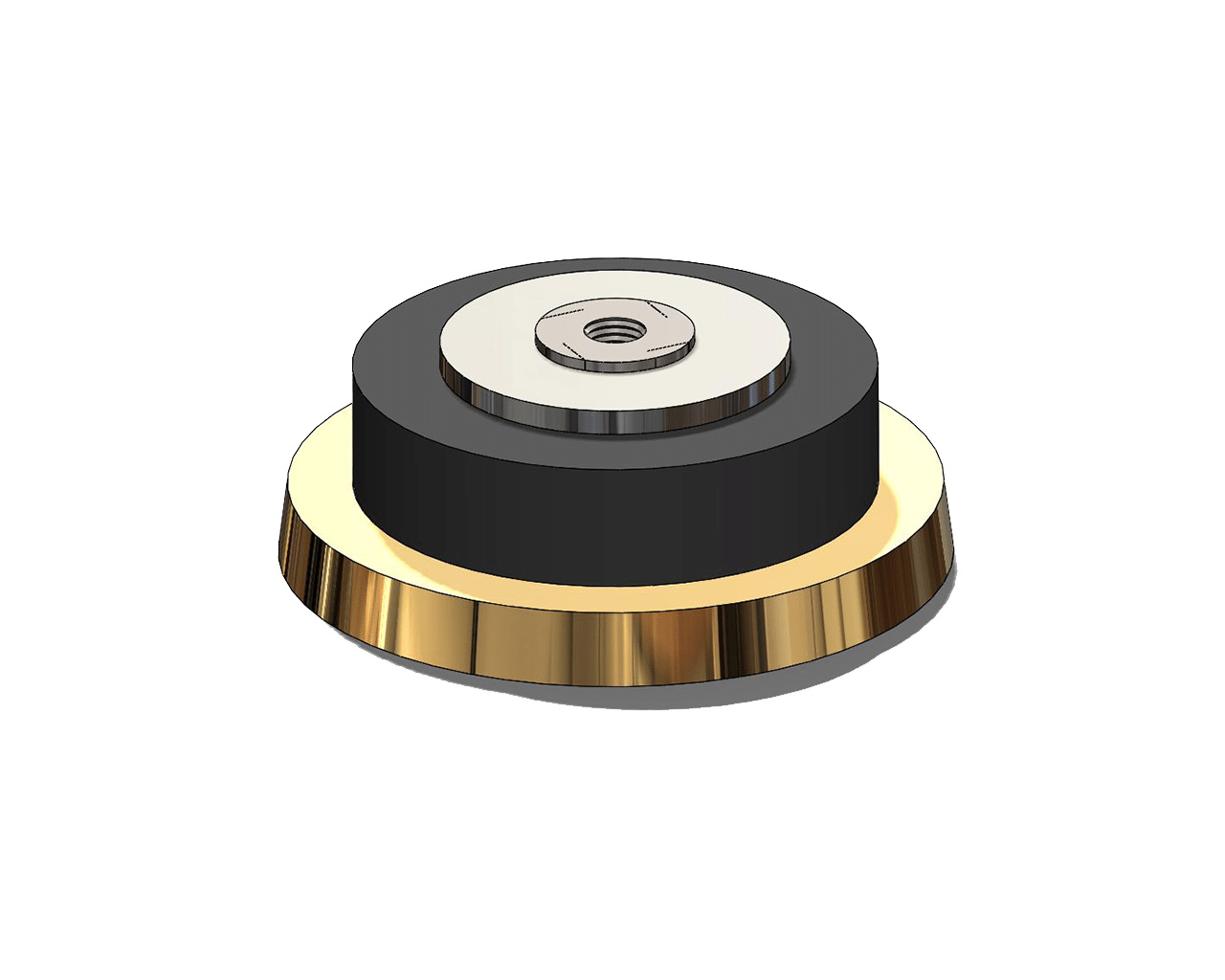

The MagFly® AP is equipped with a patented foot and spring system. This creates a gap between the steel surface and the magnets so that the magnet can be moved flexibly across the formwork table before activation. Only when light pressure is applied to the magnet from above is this gap closed, the magnet activated and the adhesive forces come into play.

Compatible with other BT products

The MagFly® AP can be combined with the MultiForm and MultiForm Alu. The formwork beam allows the insertion of the magnets by means of special receiving pockets. After that, the formwork can be moved flexibly on the shuttering table and is only fixed securely when the magnets are activated. If a tray is not positioned correctly, it can easily be realigned because the magnets can be easily and quickly deactivated again by the integrated lever.

Custom solutions

The MagFly® AP itself offers little possibility for combination with various attachments for the production of custom solutions. However, BT has developed the MagFly® universal magnet for this purpose, which can be combined with a variety of attachments to serve the customer’s exact application. You can find more information about the universal magnet here: MagFly® Universal Magnet.

Questions and answers about the product

What should I pay attention to when handling the magnets?

The general safety instructions for handling industrial magnets apply. For more detailed information, please refer to the operating instructions of the MagFly® AP.

2. how is the magnet cleaned?

The holding magnets should always be kept clean. Therefore, ideally clean the magnets after each use and, if necessary, remove concrete residues or other dirt, especially on the underside (adhesive surface). Mechanical cleaning with a wire brush is recommended. For more information, please refer to the MagFly® AP operating instructions.

3. what do I do if I need a spare part?

Spare parts for self-assembly are available at any time. Please ask your BT consultant for the spare parts list for the MagFly® AP. We will be happy to provide you with detailed repair instructions and videos for the repair. Alternatively, you have the option of taking advantage of our service offer. For customers in Germany, we offer a complete maintenance service in which any repairable defects on the magnets are repaired by us. You will receive the magnets back from us as good as new! Maintenance costs 45€ per magnet (excl. transport costs).

4. how can I store the magnets when I don’t need them?

We have developed a shelving system for storing the MagFly® AP. This allows space-saving storage of the magnets between production cycles and also ensures increased work safety. At the same time, it is possible to clean the magnets right there. The magnetic stands can be moved through production by crane or trolley, eliminating the need for time-consuming individual transport.

How can I reduce stress on the magnet?

The loads on the magnets can be significantly reduced by the splash guard specially developed by BT. Cleaning measures to remove concrete residues or repair measures can thus be reduced. The splash guard is simply hooked into the MultiForm before concreting, and thus protects the magnet from contamination during production.