Special bulkheads for battery moulds, consisting of two formwork panels connected by a robust hinge

References

Videos

Do you have any questions?

Documents & Data Sheets

What does this product have to offer?

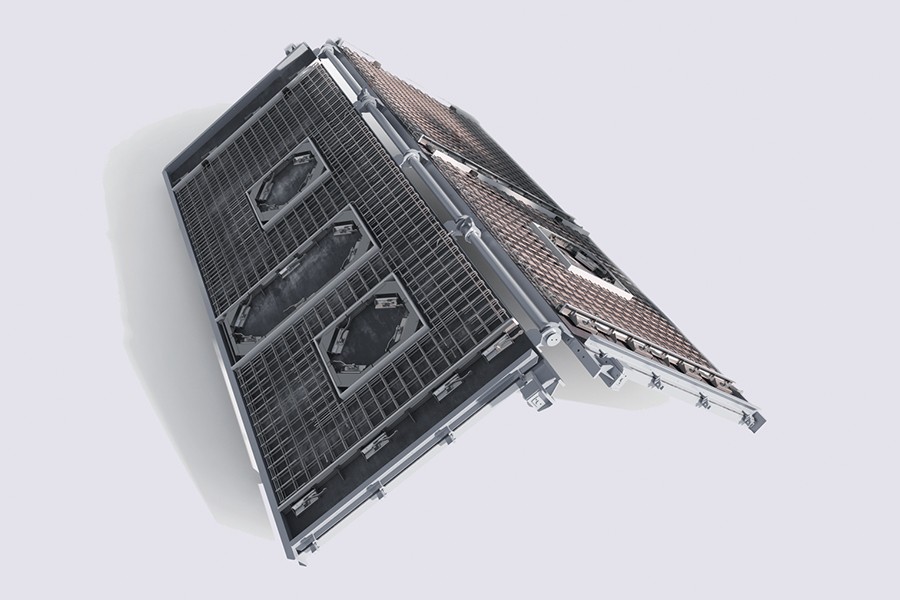

Butterfly Formworks® are special bulkheads for battery moulds. They consist of two formwork panels that are connected to each other via a robust hinge.

Your advantages

- Successful in use with market leaders

- Combination of advantages of horizontal and vertical production

- Increase capacity and productivity (up to 3 times compared to tilt table)

- Small floor area requirements (approx. 1/3 compared to tilting table)

- Lower investment costs than tilting table

- Reduction of production costs by up to 40%

- Effiziente, kostengünstige Heizsysteme durch kompakte Bauweise

- 5-sided formwork-smooth precast concrete elements

- Naht- und fugenlose Schalungsflächen bis zu 12,0m x 4,5m

- High flexibility for solid wall, sandwich wall, facade elements, balcony slabs

- Special products: Solid ceiling, protective walls, retaining and bulkhead walls, etc.

- Use of laser projection possible (in contrast to standard battery)

- Equipment available for the entire production process (e.g. roller gears/friction wheel drive)

Product details

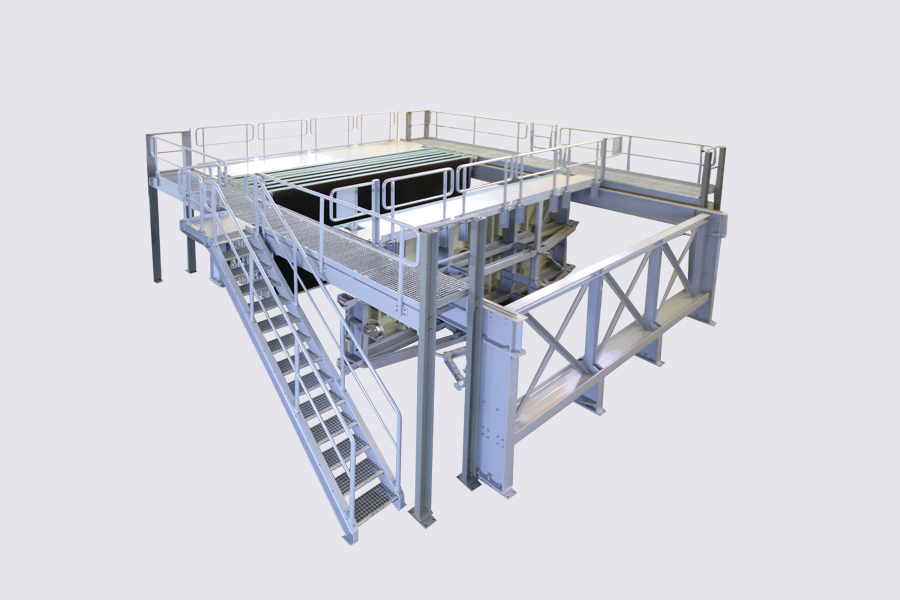

For the preparation of the precast concrete parts, especially for formwork construction, the measuring and insertion of built-in parts, as well as the insertion and fixing of reinforcement, these Butterfly Formworks® are taken out of the battery formwork and folded open. They can then be transported horizontally like circulating pallets to different work stations. After all preparation activities have been completed, the butterfly formwork is folded up again and fed to the Battery Mould.

Horizontal preparation and vertical production. Butterfly folding formwork combines the specific advantages of horizontal preparation with the vertical concreting of prefabricated reinforced concrete elements.

All preparatory work is effectively carried out horizontally: from measuring with laser projection equipment (or marking with a plotter), to formwork construction, positioning of the built-in components, to placing the reinforcement. This principle is known and proven in circulation systems, stationary conveyors and tilting tables.

Using the advantages of battery mould: B.T. innovation GmbH developed the patented Butterfly Formwork® and turns battery formwork into a Butterfly Battery® Mould.

Parallel workflows at the horizontal indexing tables outside the battery significantly reduce the set-up time.

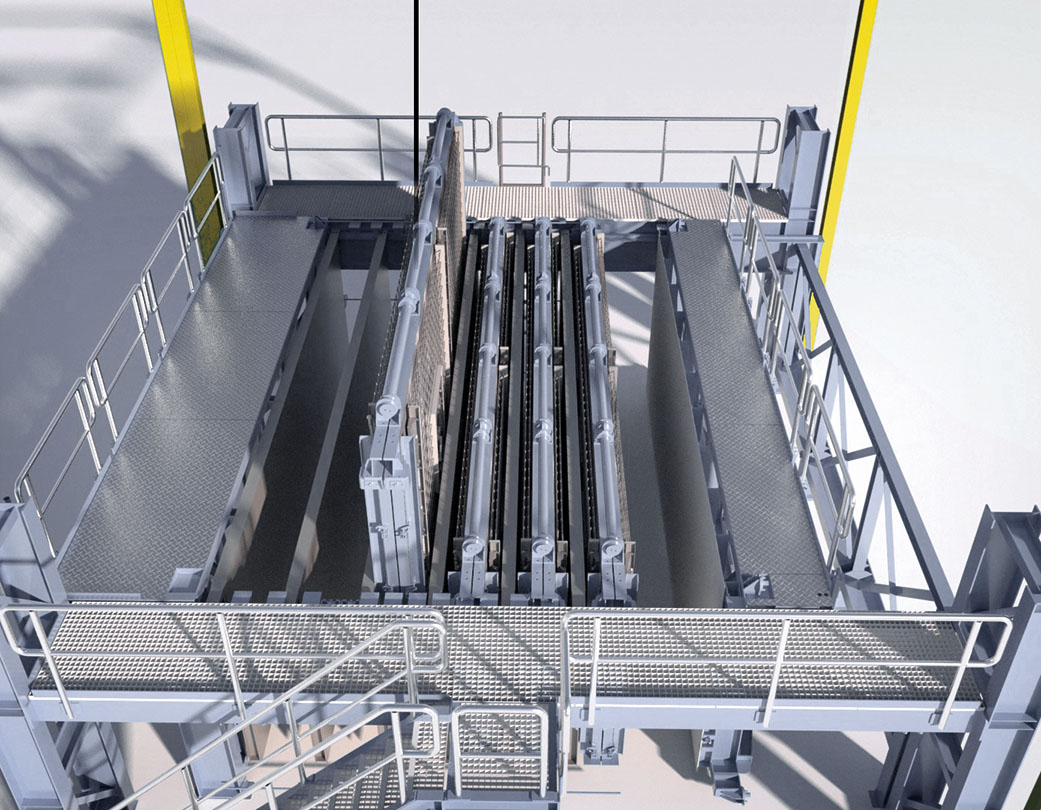

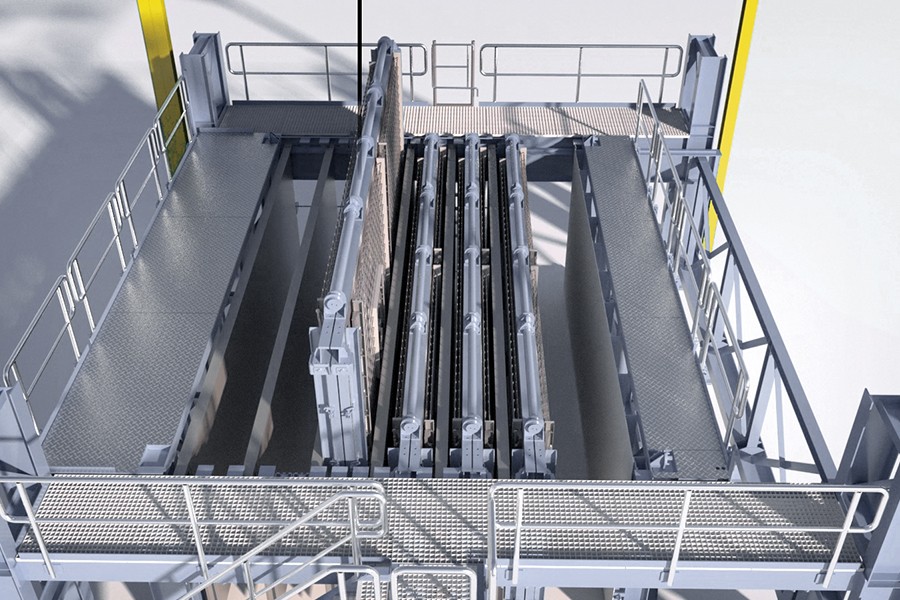

Once the preparation is complete, the formwork surfaces are raised. When lifted, the formwork folds up in the middle – like the flight of a butterfly, which gives the new system its name.

The formwork face is thus brought from the horizontal preparation position to the vertical concreting position. The butterflies prepared in this way are lifted directly into the battery mould.

With the release of the crane hook, two battery compartments are ready for concreting: solid walls, sandwich walls, façade elements and balcony slabs in five-sided formwork smooth. Not a single work step in the narrow battery mould itself is necessary.

The battery formwork is completely assembled and concreted with the prepared formwork within a very short time. Already at strength of 3-8N/mm² the finished parts can be removed from the battery together with the butterflies and stored outside the battery for curing. Previous experience of our customers shows that several sets of the folding formwork make up to 4 concreting passes possible within 24 hours with the Butterfly Formwork®. When using a duplex battery, higher turnover rates are possible.

The Butterfly Formwork® can be used without battery as a substitute for a tilting table. The installation of structural matrices in a horizontal position is usually much less complicated than with vertical formwork surfaces. The Butterfly Formwork® is also suitable for a combination of horizontal and vertical concreting, e.g. for façade slabs. The ashlar or clinker facing layer can be concreted horizontally; the base course is then produced upright in the battery formwork for a formwork-smooth inner wall surface.

* BT innovation sells the Butterfly Formwork® and Butterfly Battery® Mould for stationary applications on the basis of an exclusive license from NEULANDT GmbH.