Multiply the capacity and productivity of battery formwork

References

Do you have any questions?

What does this product have to offer?

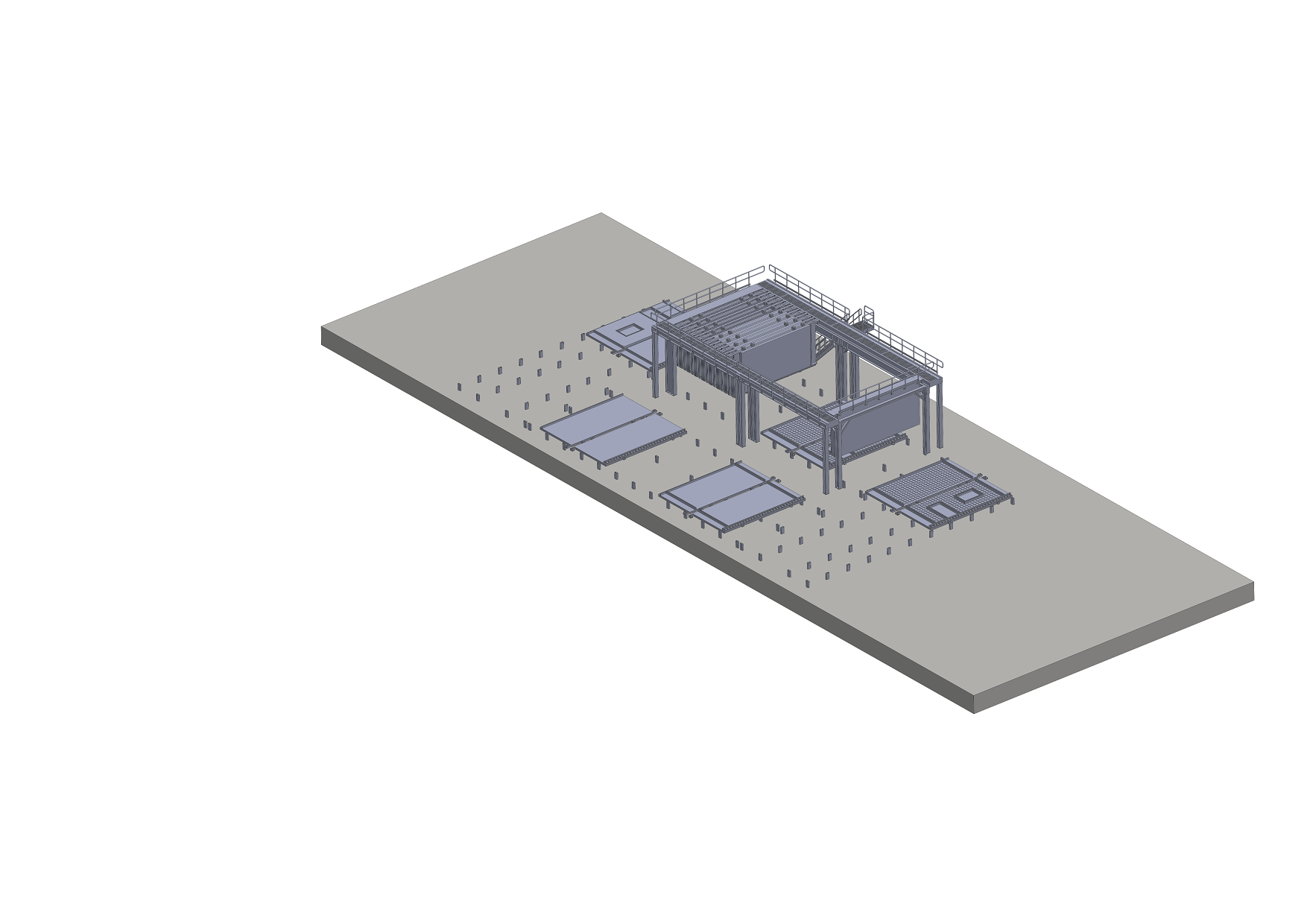

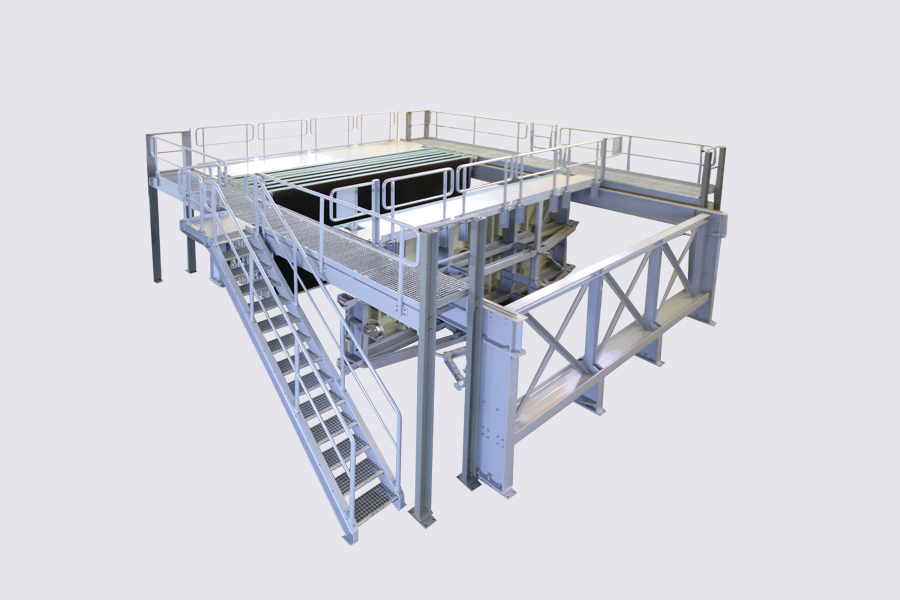

The centre of the circulation system is a Butterfly Battery® Mould. The butterfly Formworks® are prepared lying down in a circuit around the battery formwork, at specialised stations, and then automatically hung into the battery formwork. This doubles the capacity of the battery formwork.

Your advantages

- Formwork-smooth main visible sides of the precast concrete elements

- High-precision prefabricated parts for direct use or for modular construction

- Highly productive battery formwork

- Compatible with common robot technology (laser, formwork robot, mesh welding system, etc.)

- Production of sandwich walls with formwork-smooth main visible sides

- Optimized goods logistics along the production line

Product details

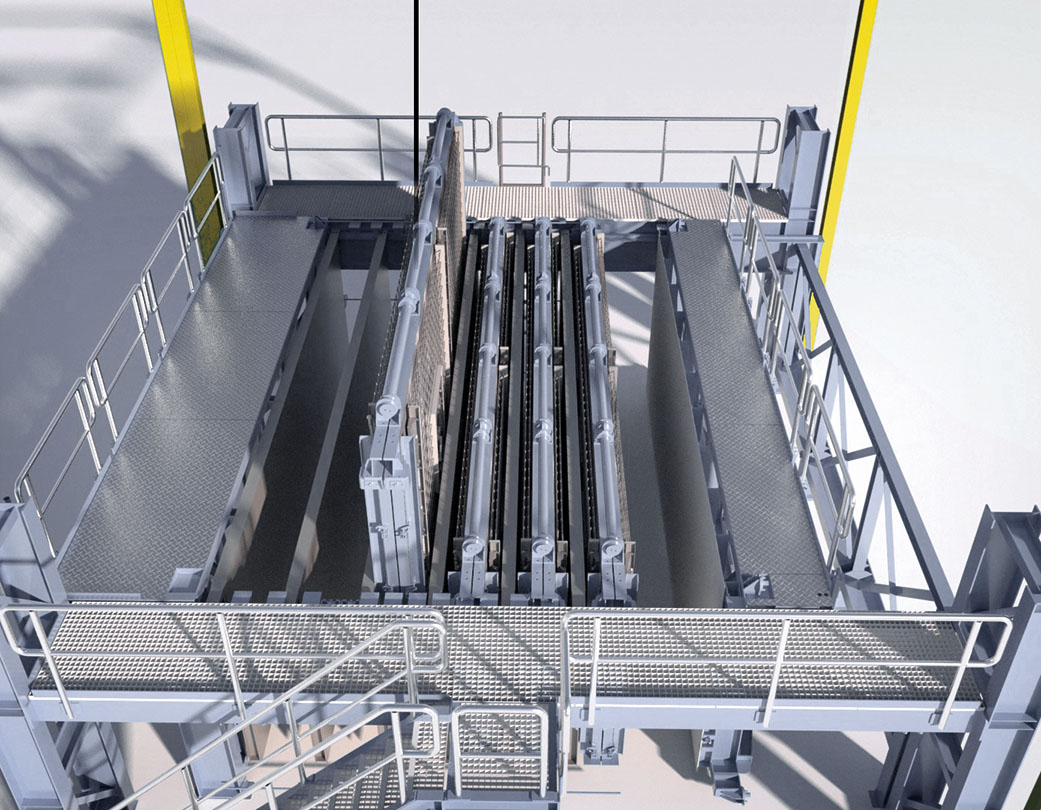

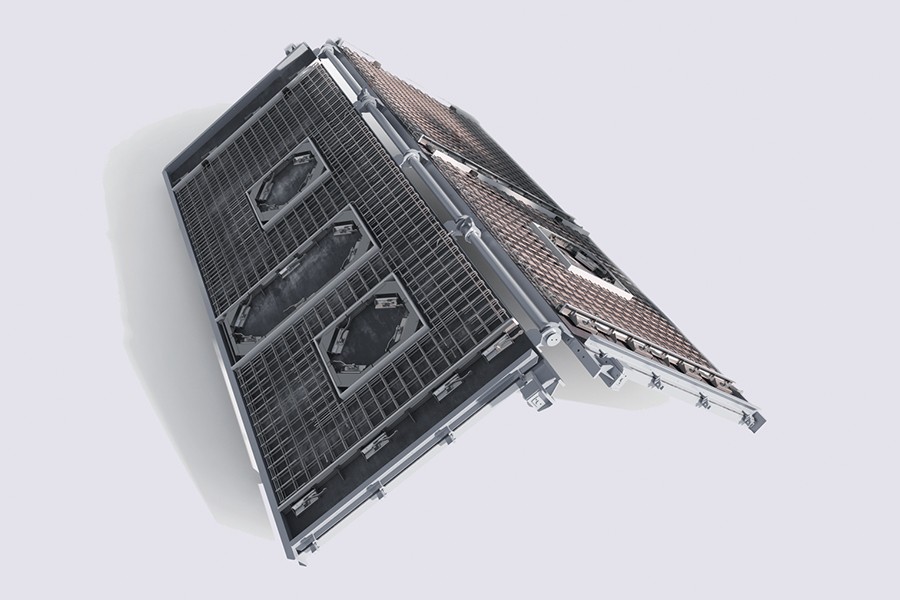

At the center of the circulation system is a battery formwork with suspended bulkheads. The battery formwork is equipped with Butterfly Formworks®, which doubles the capacity of the battery formwork, as two concreting chambers have now been formed in the bulkhead due to the use of the Butterfly Formwork®.

The Butterfly Formwork® is prepared lying down in a circulation around the battery formwork, at specialised stations. This technique allows the flow of goods through the production facility to be kept lean and the Butterfly Formwork® to be prepared in short cycle times.

The Butterfly Formwork®, prepared lying down, is automatically guided through the production facility and mounted in the battery formwork.

After bracing the battery formwork, it is concreted. Once the concrete has hardened, the precast concrete elements together with the Butterfly Formwork® can be removed from the battery formwork, even before it has reached its lifting strength, which means that the battery formwork is available for several repositionings per day.

With this technology, Butterfly Formwork® is prepared quickly and accurately, and the battery formwork is loaded quickly. As a result, the capacity and productivity of the battery formwork are multiplied.

If an additional bypass station is created, in which prepared Butterfly Formwork® can be temporarily stored partially concreted, the accessibility of sandwich walls in the battery formwork is also possible without any problems.

Areas of application

- Production line in a precast plant