Channel sealing with BT innovation

In recent years, a number of serious structural defects and leaks have been identified in Germany in the area of public wastewater supply and property drainage. Depending on local conditions, this can lead to problems caused by infiltration of groundwater, strata water or seepage water. A consequence of this is increased combined sewer overflows in the combined sewer system as well as additional pollution of water bodies.

Effect of infiltration

Wastewater measurements that contain an increased amount of extraneous water can be expected to have a negative impact on treatment plant performance. As a result of dilution, the degradation performance of the wastewater treatment plant suffers, which in turn leads to more pollutants being added to water bodies. In addition, wastewater treatment plants exhibit greater energy and cost efficiency as hydraulic loads are increased to allow pumps and lift stations to operate more.

Furthermore, those spillway structures are affected that normally limit the wastewater to a certain extent during heavy rainfall before it is treated at the treatment plant. They fill up more quickly, which is why wastewater is discharged more frequently into waterways to relieve the burden on wastewater treatment plants through combined sewer overflows. As a result, more unfiltered wastewater is discharged into water bodies.

BT sealing products are excellent for this purpose:

- Repair structural defects and leaks in the sewage system

- Reliable sealing for retrofitting as well as for new sewer constructions

Thus, channel sealing with products from B.T. innovation is quick and easy to implement.

BT solutions for reliable channel sealing

Particularly often, weaknesses in surface treatment lead to leaks such as cracks in the sewer structures. Since it is our aspiration to treat the environment with care, efficient solutions are needed. Subsequent sealing is often not easy, as water is present from inside and outside the affected areas. For this reason, it is essential to have a relatively dry environment as well as to remove dirt and grease residues from the concrete so that the waterproofing material can continuously adhere well.

Causes of leaks

As a rule, water engineering systems such as sewage systems, wastewater tanks or sewage treatment plants are exposed to a wide range of loads. External causes such as mechanical impacts from traffic, construction machinery, ground movements (subsidence, subsoil subsidence), periods of frost or drought, and penetrating roots can be reasons for the damage that has occurred. In addition, defective pipe joints, defective pipes and materials, the seals, as well as inadequate pipe network conditions affect due to persistent corrosion.

InnoElast® – Effective sealing of joints and cracks in facades

The InnoElast® Type 2 sealant is suitable for subsequent reliable sealing against water under pressure. The pasty InnoElast® Type 2 is sprayed into the joint for sealing, where it hardens into a rubber-like material and thus seals the joint.

Advantages of InnoElast® Type 2:

- No primer required

- Can also be applied to damp substrates

- Processing from -3°C on ice-free surfaces

- Tested pressure waterproof up to 4,8 m water column

- High chemical resistance

Application:

Using a tubular bag gun, InnoElast® Type 2 is applied to a clean substrate and then cures effectively. The skin formation time is between 2 and 3 hours (type 1) and 15 minutes (type 2) at a room temperature of 23°C and humidity of 50%, the curing time is 3mm in 24 hours. A primer is not required beforehand. However, it is recommended to insert a joint filler cord and tape the edges. Pressing and smoothing creates a strong bond with the joint edges.

Instructions - Processing as a joint sealant

RubberElast® – joint tape for reliable sealing of component joints

Sealing during the assembly of precast elements is easy and efficient with RubberElast®. The self-adhesive RubberElast® tape is compressed for sealing between the construction elements and thus permanently seals the joints. Assembly, sealing and filling are thus possible in one day.

Advantages of RubberElast®:

- Simplest processing

- Immediately after mounting waterproof

- Processing even at low temperatures from -10°C

- Tested pressure waterproof up to 5 m water column

- Waste water, acid, alkali, salt resistant

Application:

RubberElast® can be processed quickly and without further aids. It is self-adhesive and is glued to one side of a component surface. The precast parts are then assembled and the RubberElast® is compressed in the component joint so that the component joint is filled. The joint is immediately watertight after grouting. The material remains permanently elastic and thus seals the joints permanently. Installation should be carried out in the temperature range from -10 °C to +40 °C. RubberElast® retains its elasticity even at low temperatures.

Instructions - Processing RubberElast®

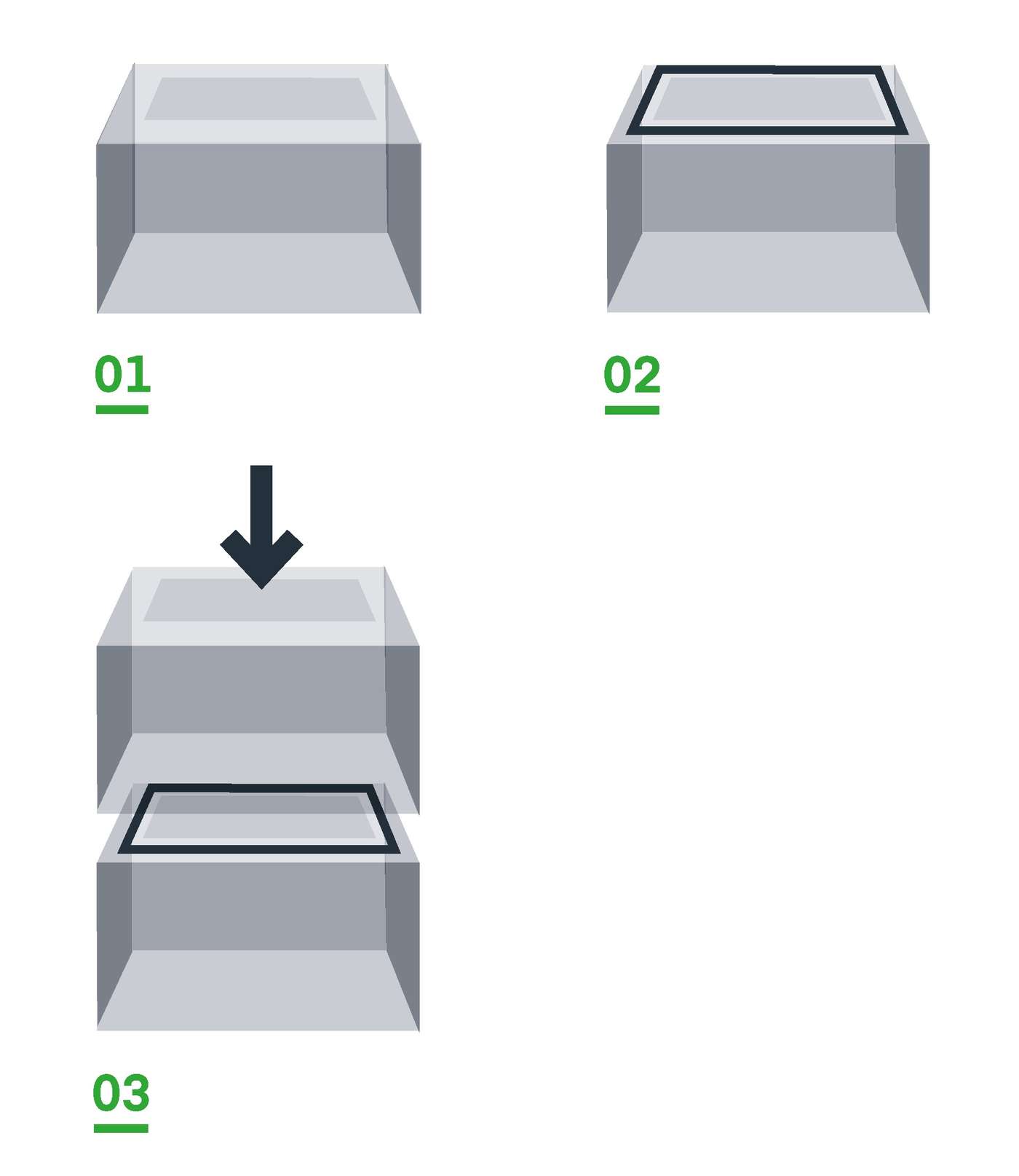

Step 1

Set precast concrete element.

Step 2

Apply RubberElast® to the component to be sealed (substrate must be free of dirt, grease and oil).

Step 3

Place precast concrete component (press components together for vertical joints), compressing RubberElast® by 80%.