ThermoPin® - optimising insulation performance by eliminating thermal bridges

The ThermoPin® is an approved bond anchor for core-insulated double walls and sandwich walls. In contrast to stainless steel connectors, when using GRP composite anchors according to FDB Merkblatt No. 3, the U-value of a sandwich wall to be produced is to be considered undisturbed. The insulation can thus develop its optimal insulating performance when using the ThermoPin. You can find more information about the ThermoPin® here.

Our sustainability commitment:

- The use of ThermoPin® provides measurable added value in building use and contributes to improving the CO2 balance of the building.

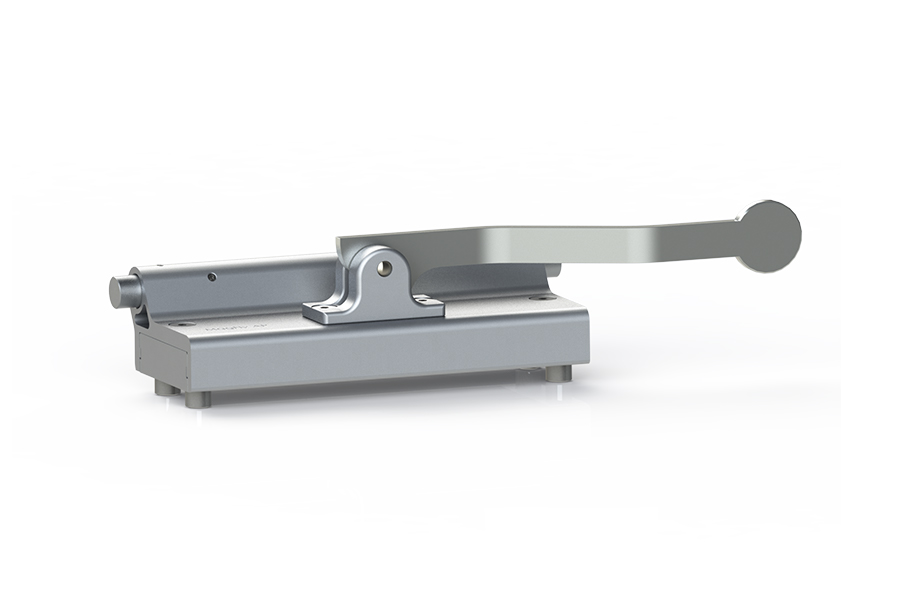

BT-Spannschloss® - Reduced environmental impact due to greatly reduced assembly times

The approved BT-Spannschloss® is a simple shell-shaped steel component. It allows the connection of up to three precast concrete elements by a simple screw connection. Tolerances of up to +/-2 cm also allow for problem-free construction progress, even in the event of unforeseen, incorrect installation of the fasteners. There is no need for time-consuming welding or potting work to achieve the load-bearing capacity of the connection. The elimination of the grouting work makes the installation independent of the weather. For more information on the BT-Spannschloss®, click here.

Our sustainability commitment:

- Construction phases and projects can be carried out more quickly.

- Crane times and workload are reduced so that more projects can be completed in the same amount of time.

- Prefabricated parts are pre-produced in high quality for the respective construction phases, so that a smooth and time-efficient process is possible on the construction site.

- Assembly / disassembly possible: Thanks to our patented BT-Spannschloss® connection system, temporarily required structures can be assembled and also disassembled again in a short time.

- BT-Spannschloss® is designed for long life and is efficiently effective throughout the life of the structure.

BT Q-Anchor - Saving resources through the possibility of thinner-walled construction

The BT Q-anchor is an insert that is installed in the formwork before concreting and is cast in the concrete. The anchor is characterised by the transmission of tensile forces and very high shear forces. The BT Q anchor enables thinner-walled construction or brings savings by minimising the use of anchoring points.

Our sustainability commitment:

- Construction phases and projects can be carried out more quickly.

- Crane times and workload are reduced so that more projects can be completed in the same amount of time.

- Prefabricated parts are pre-produced in high quality for the respective construction phases, so that a smooth and time-efficient process is possible on the construction site.

- Assembly / disassembly possible: Thanks to our patented BT-Spannschloss® connection system, temporarily required structures can be assembled and also disassembled again in a short time.

- BT-Spannschloss® is designed for long life and is efficiently effective throughout the life of the structure.

BT Q-Anchor - Saving resources through the possibility of thinner-walled construction

The BT Q-anchor is an insert that is installed in the formwork before concreting and is cast in the concrete. The anchor is characterised by the transmission of tensile forces and very high shear forces. The BT Q anchor enables thinner-walled construction or brings savings by minimising the use of anchoring points.

Our sustainability commitment:

- Resource saving (cement, sand, etc.)

- Optimisation of the transport

- Increase in production efficiency (less concrete, fewer inserts)

- Optimised crane operations

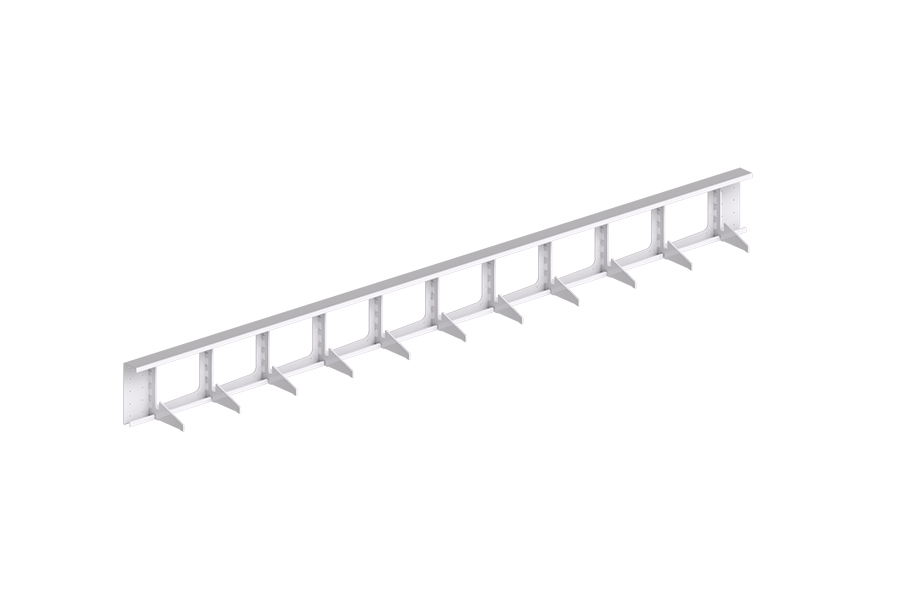

MultiForm and MagFly® AP - substitutes for resource-intensive disposable formwork made of wood

The BT formwork system, consisting of the formwork girderMultiForm andMagFly® AP,is characterised above all by its durability and ease of handling. These aspects ensure rapid amortisation and highly efficient commissioning.

Our sustainability commitment:

- Reduction of costs in procurement and disposal

- Savings in the use of materials, e.g. wood

MultiForm Alu - Reduction of lever loads

Increasing demands on formwork and plant technology in the production of precast concrete elements require the introduction of additional occupational safety measures by employers. Especially when peeling by hand, the use of cranes is often indispensable in order to comply with the guidelines of the German Load Handling Ordinance. However, handling the crane is relatively time-consuming and thus delays production. To solve this problem, we have further developed our patented MultiForm tray. The result is a lightweight, yet dimensionally stable and robust formwork beam made of specially coated aluminium.

Due to the reduced dead weight, MultiForm Alu weighs less than half compared to other beam systems, even with the formwork timber mounted.

Our sustainability commitment:

- Cost saving due to low transport weight

- Saving of the packaging material

- Time and money saved by transporting with fewer personnel

- Time and money saved by dispensing with crane systems

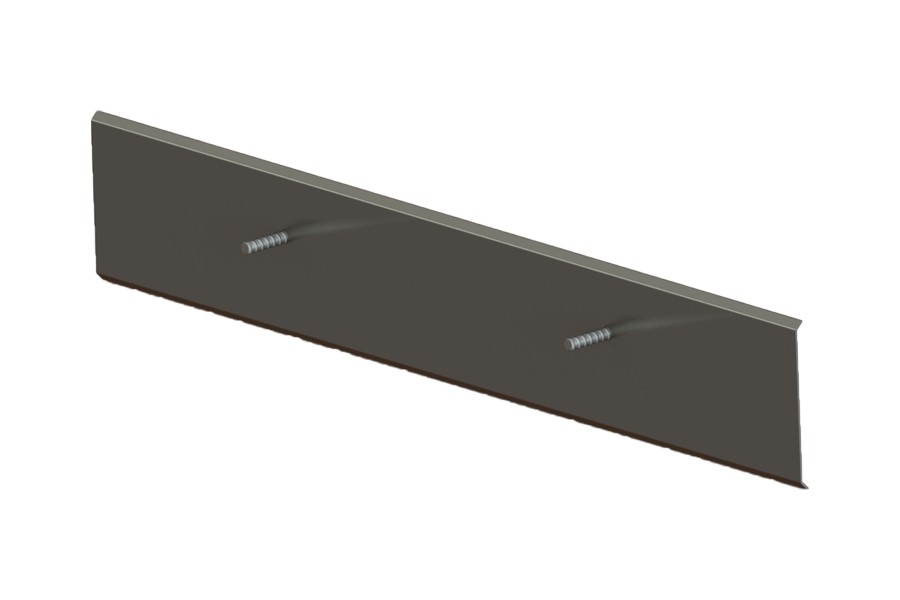

U-profile adapter pieces - use of environmentally friendly resources

The U-profile formwork system is characterised by permanently installed magnets. The magnets are activated by pressure from above and deactivated by a release lever. For the use of the U-profile on the formwork table, we have developed reusable adapter pieces made of sheet metal, which are an environmentally friendly alternative to the use of Styrofoam.

Our sustainability commitment:

- Use of extension pieces made of sheet metal instead of styrofoam

- Disposal of polystyrene not applicable

Syflex® - Durable product for reducing wood consumption

Working with formwork often means a lot of effort – both in terms of working time and costs. This is the case, for example, when heavy, large-format steel elements have to be moved with cranes or complicated formwork has to be created from a lot of wood and formwork panels in laborious manual work. BT innovation goes its own way with its Syflex formwork system: Syflex® combines the advantages of a flexibly applicable formwork with an extremely low weight. In addition, working time is saved during handling.

Our sustainability commitment:

- Reusable up to 30 times

- Material saving

- No auxiliary materials, no screwing necessary

- Reusable eccentric

UniForm - Durable product for reducing wood consumption

UniForm® is a permanent steel formwork facing. Scarf skins made of wood can usually only be reused a few times without the quality of the elements suffering. This results in significant ongoing material costs. The steel formwork skins, on the other hand, can be reused much more frequently and thus form a resource-saving alternative for the repeated production of similar precast concrete elements. For more information, click here.

Our sustainability commitment:

- No sawing, unscrewing and throwing away

- High reusability

- Permanent material savings

Sealants to protect the environment from substances hazardous to water

AgrarElast - Joint sealant for the protection of the environment against water polluting substances

For the renovation and new construction of facilities for the storage, filling and transfer of liquid manure, slurry and silage leachate (JGS), only construction products may be used that have the corresponding building authority approvals and comply with the regulations of the Waste Water Ordinance – AbwV. The joint sealant AgrarElast is a DIBt-approved joint sealant for these JGS and biogas plants. AgrarElast can be used to permanently seal precisely these storage and filling facilities, e.g. mobile silos, fermentation feed silos and solid manure plates. The system allows sealing of all joint combinations between concrete and asphalt and convinces with its high permissible deformation of 12.5 % as well as its very high temperature resistance. In addition to joint sealing in new buildings, the system is used for the renovation and repair of these installations.

Our sustainability commitment:

- With the AgrarElast, permanent protection of the environment from substances generally hazardous to water such as slurry, liquid manure and silage leachate is possible.

- Component and movement joints can be permanently sealed.

Agrar-SynkoElast - Working joint tape for the protection of the environment against water polluting substances

Agrar-SynkoElast is an internal sealing tape for construction joints. It is to be laid on set, solid concrete before further concreting with fresh concrete. It is the only joint tape approved by DIBt for this application for sealing construction joints in JGS and biogas plants, slurry tanks, mobile silos, fermentation feed silos and solid manure plates.

The high belt flexibility allows curves and corners to be formed easily during assembly. Unlike metal waterstops, the internal strip allows small distances to the outer wall and reinforcement. A quick, easy repair is possible by putting on a new tape during assembly.

Our sustainability commitment:

- Permanent protection of the environment by sealing agricultural facilities against water-polluting mixtures such as slurry, liquid manure and silage leachate

- Safe sealing of construction joints up to a tank height of 4 m

Consulting - Finding solutions together

Consulting - Construction of efficient and environmentally friendly precast concrete plants

The motto “Finding optimal solutions together” is the focus of BT innovation’s philosophy and the basic idea behind how we provide our consulting services. Our approach to working with our clients is to develop an optimal solution for and together with our clients. From idea to implementation, our customers benefit from this individual approach as well as the comprehensive technological know-how and personal experience of our consultants. We take every step in the process together with our customers, analysing organisational processes, IT structures, material and information flows, planning capacity expansions or setting up new production facilities.

For more information on consulting, click here.